What Are the Advantages of Using Nickel Clad Plates?

2025-04-16T16:00:00.000Z

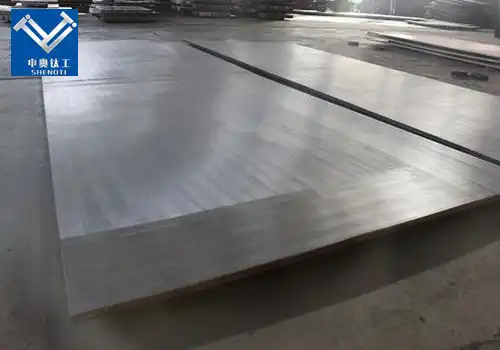

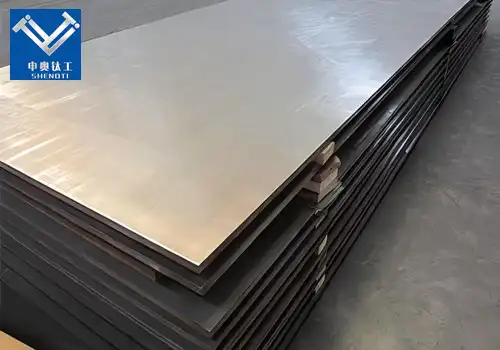

Nickel-based alloy composite plates, commonly known as nickel clad plates, have become indispensable in industries that demand exceptional corrosion resistance, mechanical strength, and cost-effectiveness. By bonding a layer of nickel or nickel alloy to a steel substrate, these composite materials combine the best properties of both metals.

Nickel Clad Plate Manufactured?

A nickel clad plate is a composite material formed by bonding a layer of nickel or nickel-based alloy to a steel substrate. This combination leverages the corrosion resistance of nickel and the structural strength of steel, resulting in a material that performs exceptionally well in harsh environments.

Manufacturing Processes

The production of nickel clad plates involves several sophisticated techniques to ensure a strong metallurgical bond between the nickel layer and the steel base:

Explosion Bonding: This method uses controlled explosive energy to bond the nickel and steel layers. The high-pressure impact creates a metallurgical bond without melting the metals, preserving their individual properties.

Hot Rolling: In this process, the nickel and steel layers are heated and passed through rollers, bonding them under high temperature and pressure. This technique is suitable for large-scale production and results in a uniform bond.

Cold Rolling: Here, the metals are bonded at room temperature through rolling, followed by heat treatment to enhance the bond strength. This method is energy-efficient and ideal for producing thin composite plates.

Explosion-Roll Bonding: Combining explosion bonding and rolling, this hybrid method first bonds the metals using explosive energy and then refines the bond through rolling, ensuring both strength and uniformity.

What Are the Advantages of Using Nickel Clad Plates?

Nickel clad plates offer a multitude of benefits that make them a preferred choice in various industries:

Superior Corrosion Resistance

Nickel's inherent resistance to corrosion, especially in acidic and alkaline environments, makes it ideal for applications in chemical processing, marine, and petrochemical industries. The nickel layer acts as a barrier, protecting the steel substrate from corrosive agents.

High-Temperature Performance

Nickel maintains its mechanical properties at elevated temperatures, making nickel clad plates suitable for high-temperature applications such as flue gas desulfurization systems and power generation equipment.

Mechanical Strength and Ductility

The steel substrate provides structural strength, while the nickel layer adds ductility, resulting in a composite material that can withstand mechanical stress and deformation without compromising integrity.

Cost-Effectiveness

By using a thin layer of nickel bonded to a less expensive steel substrate, nickel clad plates offer a cost-effective solution that delivers the desired properties of nickel without the associated high costs.

How Do Nickel Clad Plates Perform in Corrosive Environments?

Nickel clad plates are engineered to excel in environments where corrosion is a significant concern:

Chemical Processing

In chemical plants, equipment is often exposed to aggressive chemicals. Nickel clad plates resist corrosion from acids, alkalis, and other reactive substances, ensuring longevity and safety.

Marine Applications

The marine environment poses challenges like saltwater corrosion. Nickel's resistance to chloride-induced corrosion makes nickel clad plates ideal for shipbuilding, offshore platforms, and desalination plants.

Oil and Gas Industry

In oil and gas extraction and processing, equipment faces corrosive fluids and gases. Nickel clad plates provide the necessary protection, reducing maintenance costs and downtime.

What Are the Common Applications of Nickel Clad Plates?

Nickel clad plates find applications across various industries due to their unique properties:

Flue Gas Desulfurization (FGD): Used in power plants to reduce sulfur emissions, nickel clad plates withstand the acidic conditions within FGD systems.

Pressure Vessels and Heat Exchangers: In chemical and petrochemical industries, these components require materials that can handle pressure and corrosive substances, making nickel clad plates an excellent choice.

Pulp and Paper Industry: The processing chemicals used in this industry are corrosive. Nickel clad plates enhance equipment lifespan and reliability.

Civil Engineering: For structures exposed to harsh environments, such as bridges and coastal infrastructure, nickel clad plates offer durability and resistance to environmental degradation.

Conclusion

Nickel-based alloy composite plates, or nickel clad plates, represent a significant advancement in material engineering, offering a combin

Nickel-based alloy composite plates, or nickel clad plates, represent a significant advancement in material engineering, offering a combination of corrosion resistance, mechanical strength, and cost efficiency. Their versatility and performance make them an invaluable asset in industries ranging from chemical processing to marine engineering.

Contact Us

For more information on nickel clad plates and how they can benefit your specific applications, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to provide you with tailored solutions to meet your material needs.