Why Choose Aluminum Stainless Steel Clad Plate?

2025-07-12 11:19:09

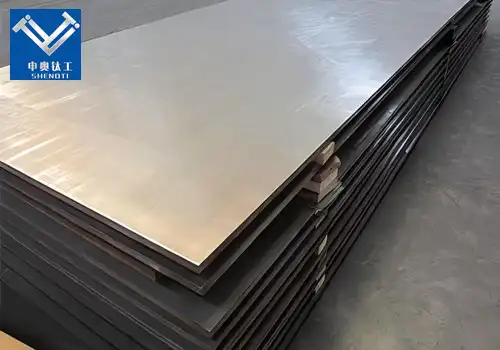

What Is an Aluminum Stainless Steel Clad Plate?

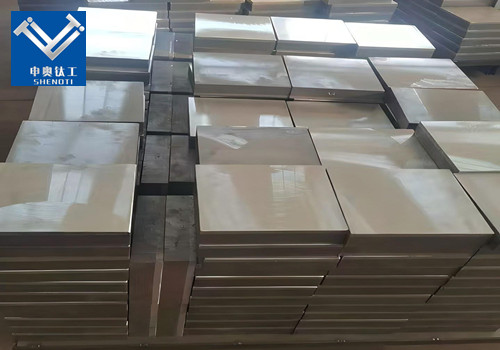

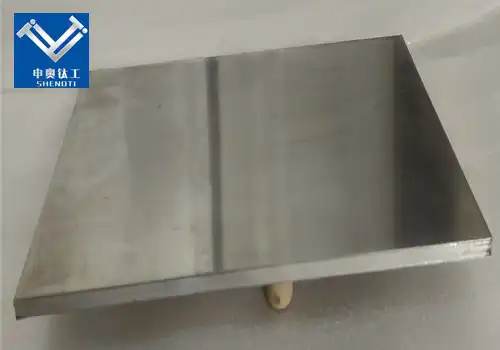

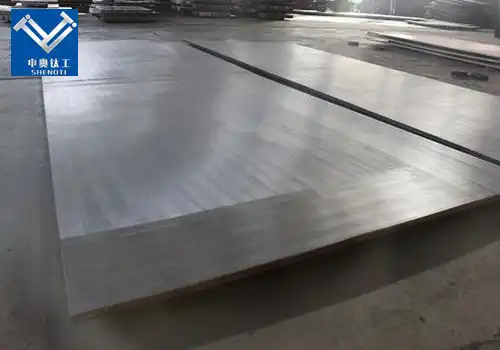

An Aluminum stainless steel clad plate is a composite material made by bonding an aluminum layer to a stainless steel substrate through advanced technologies like explosion bonding, hot rolling, or diffusion welding. This innovative metal composite combines the corrosion resistance and strength of stainless steel with the lightweight and thermal conductivity of aluminum, resulting in a versatile material suitable for a wide range of industrial and commercial applications.

Why Choose Aluminum Stainless Steel Clad Plate?

1: Enhanced Mechanical Properties

The unique fusion of aluminum and stainless steel offers the best of both worlds:

High tensile strength from stainless steel

Lightweight and ductile nature of aluminum

Thermal conductivity ideal for heat exchangers

Excellent fatigue resistance and formability

This makes aluminum stainless steel clad plate a reliable material for projects where structural integrity and weight savings are critical.

2: Corrosion Resistance

Stainless steel's oxidation resistance protects the material in acidic, saline, and marine environments. Aluminum adds an additional passive layer of protection, significantly extending the material’s life span even in aggressive atmospheres like:

Seawater

Acidic gases

Industrial exhaust systems

3: Outstanding Cost Efficiency

Replacing solid stainless steel or aluminum with a clad plate reduces material costs without sacrificing performance. You gain:

Reduced weight (lower transportation & installation costs)

Long service life (reduced maintenance and replacements)

Competitive pricing compared to exotic alloys

Using aluminum stainless steel clad plate leads to significant cost savings in large-scale industrial projects.

Key Applications of Aluminum Stainless Steel Clad Plate

1: Heat Exchangers and Condensers

The high thermal conductivity of aluminum and the corrosion resistance of stainless steel make the aluminum stainless steel clad plate ideal for heat transfer applications. Industries using them include:

HVAC

Power plants

Petrochemical industries

2: Marine and Shipbuilding Industry

In marine environments, weight reduction is crucial for vessel performance and fuel efficiency. The use of aluminum stainless steel clad plates offers:

Corrosion resistance to seawater

Lighter hull components

Enhanced safety due to improved fatigue strength

3: Chemical Processing Equipment

Chemical plants demand materials that resist chemical attack and mechanical stress. Clad plates are used in:

Reactors

Storage tanks

Pressure vessels

They perform well under both high pressure and aggressive chemical exposure.

4: Automotive and Railway Components

The automotive industry prioritizes fuel efficiency, which is tied to vehicle weight. Using aluminum stainless steel clad plate in:

Exhaust systems

Engine heat shields

Structural supports

helps reduce mass without compromising durability.

How Is Aluminum Stainless Steel Clad Plate Manufactured?

1: Explosion Bonding Technology

This high-energy process uses controlled detonation to bond aluminum to stainless steel without melting either metal. The result is a metallurgical bond with:

Strong interfacial strength

No intermetallic compounds

Excellent shear and tensile properties

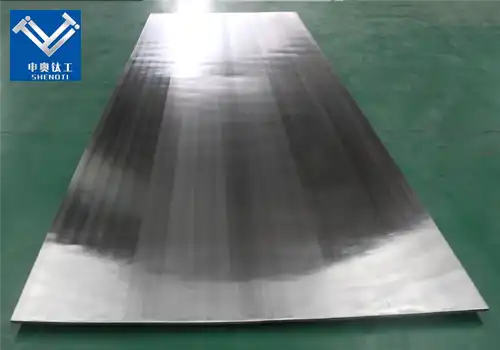

2: Hot Rolling Cladding

Hot rolling involves placing aluminum and stainless steel under extreme pressure and temperature to create a seamless bond. Benefits include:

Smooth surface finish

Excellent weldability

Uniform thickness distribution

Material Grades and Technical Specifications

The aluminum stainless steel clad plate can be customized using various material grades:

Layer Common Grades

Aluminum :1050, 1060, 3003, 5052, 6061

Stainless Steel :304, 316L, 321, 310S, 904L

Typical specifications:

Thickness range: 1.0mm to 50mm

Width: up to 2000mm

Bonding strength: ≥ 130 MPa

Corrosion resistance: ≥ 500 hours in salt spray test

Custom sizes and mechanical properties can be tailored according to project requirements.

Benefits of Using Aluminum Stainless Steel Clad Plate in Industry

1: Sustainability and Environmental Impact

Using composite plates reduces the need for rare or high-energy metals. Lighter materials also cut carbon emissions during transportation and operation.

2: Excellent Workability

The clad plates can be:

Cut

Bent

Welded

Machined

This makes them ideal for custom fabrication in various shapes and configurations.

3: High Compatibility with Modern Joining Methods

Thanks to their metallurgical bond, aluminum stainless steel clad plates are suitable for:

Friction welding

Explosion welding joints

Bimetal transition joints

These features make them ideal for composite pipelines and dual-metal equipment.

Industry Case Study: Chemical Reactor Upgrade

A major chemical plant in Southeast Asia replaced its conventional 316L reactors with aluminum-stainless steel clad versions. Results:

30% reduction in fabrication costs

Improved heat transfer by 25%

Extended service life from 8 to 15 years

No major maintenance reported after 5 years of operation

Global Standards and Quality Assurance

Reputable manufacturers of aluminum stainless steel clad plate follow standards like:

ASTM B898 (Explosion-bonded aluminum/stainless composites)

GB/T 8165 (China clad plate standard)

ASME Code Case for Pressure Vessels

Quality tests include:

Ultrasonic testing (UT)

Shear testing

Salt spray testing

Microstructure inspection

Choosing a certified supplier ensures compliance with international quality and safety regulations.

Choosing the Right Aluminum Stainless Steel Clad Plate Manufacturer

When selecting a supplier, consider the following:

Technical experience in cladding

Full material traceability

Customization capabilities

Compliance with industry standards

After-sales technical support

A good manufacturer offers not just materials, but engineering solutions tailored to your project’s unique needs.

Innovation with Aluminum Stainless Steel Clad Plate

In today’s competitive and sustainability-driven market, the aluminum stainless steel clad plate stands out as a high-performance, cost-effective, and durable solution for multiple industries. Whether your focus is on weight reduction, corrosion protection, or energy efficiency, this dual-metal composite delivers excellent value.

Ready to elevate your next project? Choose aluminum stainless steel clad plates and unlock new possibilities in material engineering.

Contact Us for Aluminum Stainless Steel Clad Plate Solutions

We specialize in customized clad metal solutions that meet global industrial demands. If you’re looking for a reliable supplier of aluminum stainless steel clad plate, contact us today:

Baoji City ShenAo Metal Materials Co., Ltd.

Email: zh@baojiti.com.cn

Website: shenaocladplate.com

Address: High-Tech Development Zone, Baoji, China’s Titanium Valley

YOU MAY LIKE

_1735019249058.webp)