What Is a Nickel Alloy Steel Clad Plate?

2025-04-18T02:49:59.000Z

What Is a Nickel Alloy Steel Clad Plate?

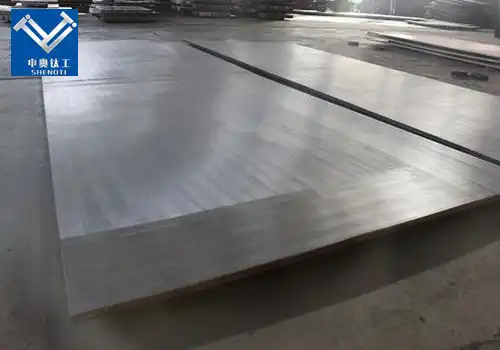

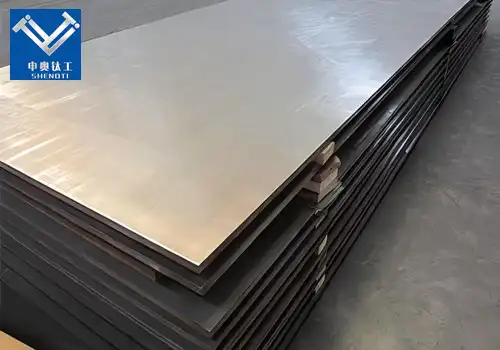

Nickel alloy steel clad plates are engineered composite materials that combine the mechanical strength of carbon or low-alloy steel with the corrosion resistance of nickel or nickel-based alloys. These plates are produced by bonding a layer of nickel or nickel alloy onto a steel substrate, resulting in a material that leverages the advantageous properties of both metals. The bonding process can be achieved through various methods, including explosive welding, hot rolling, or other metallurgical techniques, ensuring a strong and durable union between the two layers.

According to ASTM A265, these clad plates are designed for applications requiring a combination of corrosion resistance and structural integrity, such as in chemical processing, power generation, and marine environments .

What Are the Advantages of Nickel Clad Steel Plates?

Nickel clad steel plates offer several benefits that make them suitable for demanding industrial applications:

Corrosion Resistance

Nickel provides excellent resistance to corrosion, particularly in acidic and high-temperature environments. This property is crucial for industries like chemical processing and marine engineering, where materials are exposed to harsh conditions .

Mechanical Strength

The steel substrate imparts high mechanical strength and durability to the clad plate, making it capable of withstanding significant structural loads and stresses.

Cost-Effectiveness

By combining a thin layer of expensive nickel alloy with a more economical steel base, clad plates offer a cost-effective solution without compromising on performance.

Versatility

These plates can be customized in terms of thickness, width, and length to meet specific application requirements, enhancing their adaptability across various industries .

How Is a Nickel Clad Plate Manufactured?

The manufacturing of nickel clad steel plates involves several key processes to ensure a strong bond between the nickel alloy and steel layers:

Explosive Welding

This method uses controlled explosive energy to bond the nickel alloy to the steel substrate. The high-pressure impact results in a metallurgical bond without melting the materials, preserving their individual properties .

Hot Rolling

In this process, the nickel alloy and steel are heated and rolled together under high pressure, promoting diffusion bonding at the interface. This technique is suitable for producing large plates with uniform thickness.

Quality Control

Post-manufacturing, the clad plates undergo rigorous testing, including shear strength, bond strength, and tension tests, to ensure they meet the required mechanical and chemical standards .

What Are the Applications of Nickel Clad Plates?

Nickel clad steel plates are utilized in various industries due to their combined properties:

Chemical Processing

Their corrosion resistance makes them ideal for equipment like reactors, heat exchangers, and storage tanks in chemical plants .

Power Generation

In power plants, these plates are used in components exposed to high temperatures and corrosive environments, such as condensers and pressure vessels.

Marine Engineering

The marine industry employs nickel clad plates in shipbuilding and offshore structures, where resistance to seawater corrosion is essential.

Oil and Gas

They are used in pipelines and processing equipment that handle corrosive substances, ensuring longevity and safety .

Aerospace

The aerospace sector utilizes these plates in components that require both strength and resistance to extreme environmental conditions.

Contact Us

For more information on nickel clad steel plates or to discuss your specific requirements, please contact us:

Email: zh@baojiti.com.cn

Our team is ready to provide you with expert guidance and high-quality solutions tailored to your needs.