What are the applications of nickel titanium clad plates?

2025-04-18T02:16:50.000Z

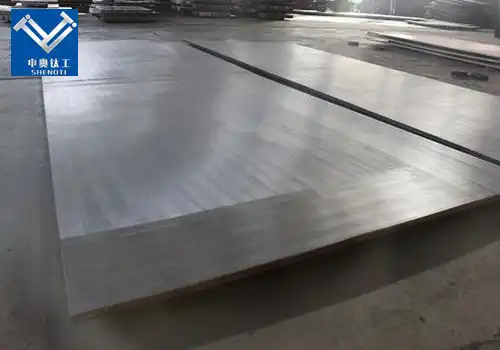

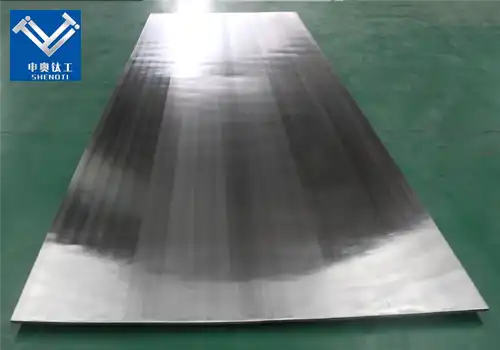

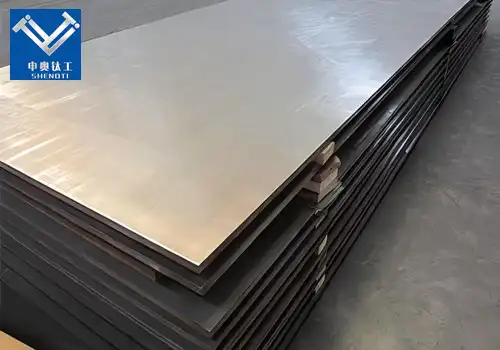

What Is a Nickel Titanium Clad Plate?

Nickel titanium clad plates are advanced composite materials that combine the unique properties of nickel and titanium to deliver exceptional performance in demanding industrial applications. These plates are engineered by bonding layers of nickel and titanium, resulting in a material that offers superior corrosion resistance, high strength, and excellent thermal and electrical conductivity. Such characteristics make nickel titanium clad plates invaluable in industries like chemical processing, aerospace, marine engineering, and power generation.

In this comprehensive blog post, we will delve into the intricacies of nickel titanium clad plates, addressing key questions that are frequently searched on Google:

What are the advantages of nickel titanium clad plates?

How are nickel titanium clad plates manufactured?

What are the applications of nickel titanium clad plates?

By exploring these questions, we aim to provide a thorough understanding of nickel titanium clad plates, their benefits, manufacturing processes, and applications.

What Are the Advantages of Nickel Titanium Clad Plates?

Nickel titanium clad plates offer a combination of properties that make them highly advantageous for various industrial applications.

Superior Corrosion Resistance

One of the primary benefits of nickel titanium clad plates is their exceptional resistance to corrosion. Nickel provides excellent protection against a wide range of corrosive environments, including acidic and alkaline conditions. Titanium, on the other hand, forms a stable oxide layer that further enhances corrosion resistance. This dual protection ensures longevity and reliability in harsh environments.

High Strength and Durability

The combination of nickel and titanium results in a material with high tensile strength and durability. This makes nickel titanium clad plates suitable for applications that require materials to withstand mechanical stress and high-pressure conditions.

Excellent Thermal and Electrical Conductivity

Nickel titanium clad plates exhibit good thermal and electrical conductivity, making them ideal for applications in the electronics and power generation industries. The conductive properties of nickel, combined with the thermal stability of titanium, allow for efficient heat and electricity transfer.

Cost-Effectiveness

By combining nickel and titanium, clad plates offer a cost-effective solution compared to using solid nickel or titanium plates. This allows industries to benefit from the desirable properties of both metals while managing material costs effectively.

How Are Nickel Titanium Clad Plates Manufactured?

The manufacturing of nickel titanium clad plates involves advanced metallurgical techniques to ensure a strong bond between the nickel and titanium layers. The primary methods include:

Explosion Bonding

Explosion bonding is a solid-state welding process that uses controlled explosive energy to bond the nickel and titanium layers. This method creates a high-quality metallurgical bond without melting the metals, preserving their individual properties. Explosion bonding is particularly effective for joining dissimilar metals like nickel and titanium.

Hot Rolling

In the hot rolling process, the nickel and titanium layers are heated to high temperatures and then passed through rollers to achieve the desired thickness and bond strength. This method allows for precise control over the plate's dimensions and ensures uniform bonding across the entire surface.

Combination of Explosion Bonding and Hot Rolling

Some manufacturers employ a combination of explosion bonding followed by hot rolling to enhance the bond strength and achieve specific mechanical properties. This hybrid approach leverages the advantages of both methods to produce high-quality clad plates.

What Are the Applications of Nickel Titanium Clad Plates?

Nickel titanium clad plates are utilized in a wide range of industries due to their unique properties.

Chemical Processing Industry

In chemical processing plants, nickel titanium clad plates are used to construct equipment such as heat exchangers, reactors, and pressure vessels. Their corrosion resistance ensures longevity and safety when handling aggressive chemicals.

Aerospace Industry

The aerospace sector benefits from the high strength-to-weight ratio and corrosion resistance of nickel titanium clad plates. They are used in components that require durability and reliability under extreme conditions.

Marine Engineering

Nickel titanium clad plates are ideal for marine applications due to their resistance to seawater corrosion. They are used in shipbuilding, offshore platforms, and other marine structures where durability is critical.

Power Generation

In power plants, these clad plates are employed in heat exchangers, condensers, and other equipment that operate under high temperatures and corrosive environments. Their thermal conductivity and corrosion resistance contribute to efficient and reliable power generation.

Conclusion

Nickel titanium clad plates represent a significant advancement in material engineering, offering a combination of properties that address the challenges of various industrial applications. Their superior corrosion resistance, high strength, and excellent thermal and electrical conductivity make them an indispensable material in industries ranging from chemical processing to aerospace. Understanding their advantages, manufacturing processes, and applications allows for informed decisions when selecting materials for demanding environments.

Contact Us

For more information on nickel titanium clad plates or to discuss your specific requirements, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with high-quality materials and tailored solutions to meet your industrial needs.