In Which Industries Are Titanium Alloy Composite Steel Plates Mainly Used?

2025-04-26 09:52:26

In Which Industries Are Titanium Alloy Composite Steel Plates Mainly Used?

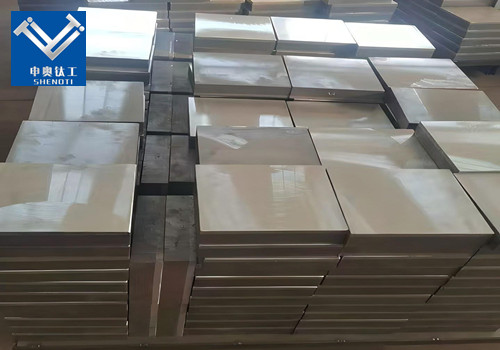

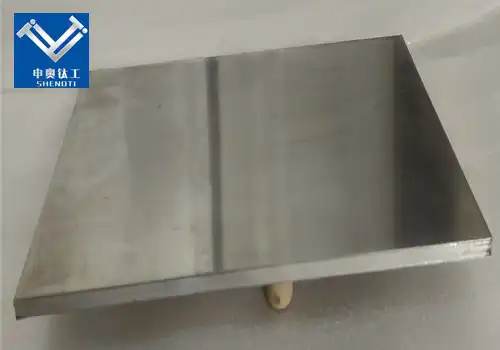

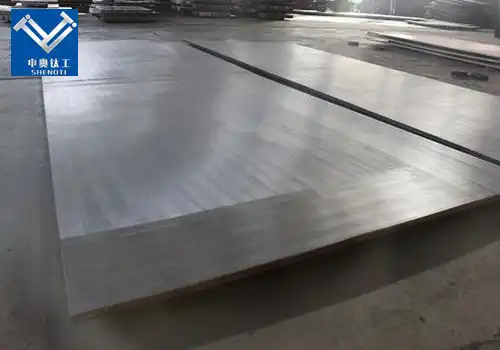

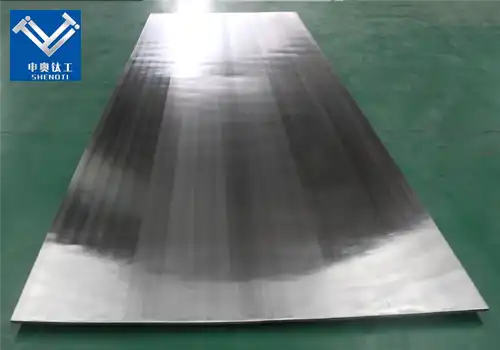

Titanium alloy composite steel plates, commonly known as titanium clad plates, have emerged as a revolutionary material in various industrial sectors. By combining the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of carbon steel, these plates offer unparalleled advantages in demanding environments.

What Are the Primary Applications of Titanium Clad Plates?

Titanium clad plates are engineered to withstand harsh conditions, making them indispensable in several industries:

1. Petrochemical and Chemical Processing Industry

In the petrochemical sector, equipment is frequently exposed to corrosive substances such as acids, alkalis, and salts. Titanium clad plates are extensively used in:

Distillation Columns and Reactors: These components benefit from titanium's resistance to corrosion, ensuring longevity and safety.

Heat Exchangers and Condensers: Titanium's thermal conductivity and corrosion resistance make it ideal for efficient heat transfer processes.

Storage Tanks: Storing aggressive chemicals requires materials that can resist degradation, a role perfectly suited for titanium clad plates.

The integration of titanium clad plates in these applications not only enhances equipment lifespan but also reduces maintenance costs and downtime.

2. Power Generation Sector

Power plants, especially those utilizing fossil fuels, face challenges related to corrosion due to flue gases and high-temperature operations. Titanium clad plates are employed in:

Flue Gas Desulfurization (FGD) Systems: These systems remove sulfur dioxide from exhaust flue gases, a process that involves corrosive environments where titanium's properties are beneficial.

Chimney Liners: Titanium's resistance to acidic condensates ensures the structural integrity of chimneys over time.

Condensers and Heat Exchangers: In both conventional and nuclear power plants, titanium clad plates facilitate efficient heat exchange while resisting corrosion.

3. Salt Production and Desalination

The salt production industry and desalination plants deal with high concentrations of chloride ions, which are highly corrosive. Titanium clad plates are utilized in:

Evaporator Shells: These components benefit from titanium's resistance to chloride-induced corrosion, ensuring consistent salt production quality.

Desalination Equipment: Titanium's non-toxic nature and corrosion resistance make it ideal for converting seawater into potable water.

4. Metallurgical Industry

In metallurgy, processes often involve aggressive chemicals and high temperatures. Titanium clad plates are essential in:

Pressure Acid Leaching Reactors: Used in extracting metals like nickel and cobalt, these reactors benefit from titanium's durability.

Processing Tanks: Handling of precious metal slags and other corrosive materials necessitates the use of corrosion-resistant materials like titanium clad plates.

How Do Titanium Clad Plates Enhance Equipment Performance?

The integration of titanium clad plates into industrial equipment offers several performance enhancements:

1. Extended Equipment Lifespan

Titanium's corrosion resistance ensures that equipment components last longer, reducing the frequency of replacements and associated costs.

2. Improved Safety

By preventing corrosion-related failures, titanium clad plates contribute to safer operational environments, especially in industries dealing with hazardous substances.

3. Enhanced Efficiency

In heat exchangers and condensers, titanium's thermal conductivity facilitates efficient heat transfer, improving overall system performance.

4. Cost Savings

While titanium is an expensive material, cladding it onto steel provides the necessary properties at a fraction of the cost, offering economic advantages without compromising on performance.

What Are the Advantages of Using Titanium Clad Plates Over Other Materials?

When compared to other materials, titanium clad plates offer distinct benefits:

1. Superior Corrosion Resistance

Unlike stainless steel or other alloys, titanium exhibits exceptional resistance to a wide range of corrosive agents, including chlorides, acids, and seawater.

2. High Strength-to-Weight Ratio

Titanium's lightweight nature combined with its strength makes it ideal for applications where weight savings are crucial, such as in aerospace or marine industries.

3. Biocompatibility

Titanium is non-toxic and biocompatible, making it suitable for applications in the medical and food processing industries.

4. Thermal Stability

Titanium maintains its properties over a wide temperature range, ensuring consistent performance in both high and low-temperature environments.

Are Titanium Clad Plates Suitable for Marine Applications?

Yes, titanium clad plates are highly suitable for marine applications due to their resistance to seawater corrosion and biofouling.

1. Shipbuilding

Components such as hulls, decks, and other structural elements benefit from titanium's durability and resistance to marine environments.

2. Offshore Platforms

In oil and gas exploration, offshore platforms are exposed to harsh marine conditions. Titanium clad plates ensure structural integrity and longevity.

3. Desalination Plants

As previously mentioned, titanium's properties make it ideal for equipment used in converting seawater to fresh water.

Contact Us

For more information on titanium clad plates and their applications, or to discuss your specific requirements, please reach out to us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with tailored solutions to meet your industrial needs.

YOU MAY LIKE

_1735019249058.webp)