In Which Industries Are Nickel-Based Alloy Composite Plates Mainly Used?

2025-05-09 15:09:23

In Which Industries Are Nickel-Based Alloy Composite Plates Mainly Used?

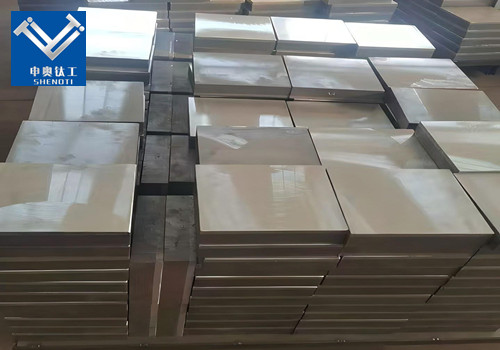

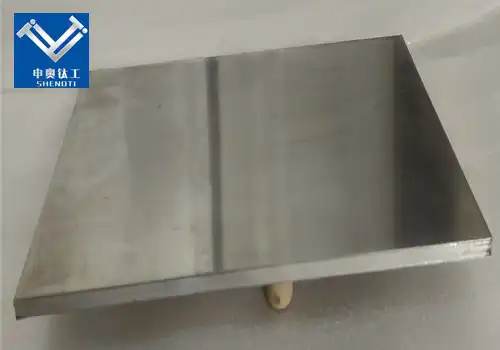

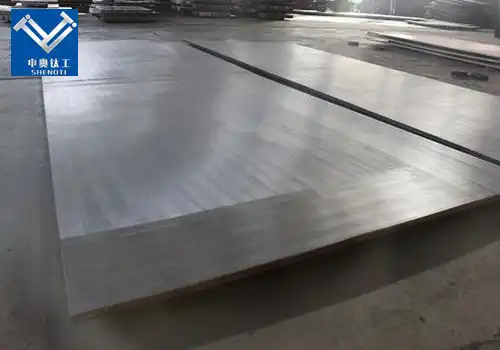

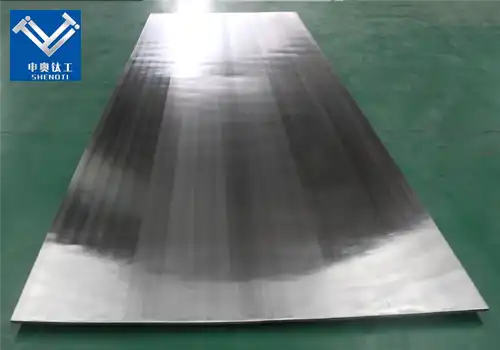

Nickel-based alloy composite plates, commonly known as nickel clad plates, are engineered materials that combine the corrosion resistance of nickel with the strength and cost-effectiveness of steel. This unique combination makes them indispensable across various industries.

What Makes Nickel Clad Plates Essential in the Chemical and Petrochemical Industries?

1. Exceptional Corrosion Resistance

Nickel clad plates is their resistance to corrosion. In chemical and petrochemical industries, equipment is often exposed to harsh chemicals, including acids, alkalis, and salt solutions. Nickel's inherent corrosion resistance makes it an ideal material for cladding, protecting the underlying steel substrate from corrosive substances .

2. High-Temperature Performance

Nickel clad plates maintain their structural integrity at elevated temperatures, which is crucial in chemical processing environments where high-temperature reactions are common. This property ensures the longevity and reliability of equipment such as reactors, heat exchangers, and piping systems .

Applications in Chemical and Petrochemical Industries

1. Reactors and Vessels: Nickel clad plates are used in the construction of reactors and storage vessels that handle corrosive chemicals.

2. Heat Exchangers: Their thermal conductivity and corrosion resistance make them suitable for heat exchangers in chemical plants.

3. Piping Systems: Nickel clad pipes are employed to transport aggressive chemicals safely.

How Do Nickel Clad Plates Enhance Performance in the Oil and Gas Sector?

1. Resistance to Harsh Environments

The oil and gas industry operates in some of the most challenging environments, including offshore rigs and deep-sea drilling platforms. Equipment in these settings is exposed to seawater, high pressures, and corrosive substances. Nickel clad plates offer excellent resistance to these harsh conditions, ensuring the durability and safety of critical infrastructure .

2. Applications in Oil and Gas

Pipelines: Nickel clad plates are used to manufacture pipelines that transport oil and gas, providing corrosion resistance and structural strength.

3. Valves and Pumps: These components benefit from the wear resistance and durability of nickel clad materials.

4. Pressure Vessels: In high-pressure environments, nickel clad pressure vessels ensure safety and longevity.

Why Are Nickel Clad Plates Preferred in Power Generation Facilities?

1. High-Temperature Stability

Power generation facilities, especially those utilizing fossil fuels or nuclear energy, require materials that can withstand high temperatures without degrading. Nickel clad plates exhibit excellent thermal stability, making them suitable for components exposed to intense heat

2. Corrosion Resistance in Aggressive Environments

In power plants, equipment is often exposed to corrosive gases and liquids. Nickel's corrosion resistance ensures that components such as boilers and heat exchangers maintain their integrity over time.

3. Applications in Power Generation

Boilers and Heat Exchangers: Nickel clad plates are used in the construction of boilers and heat exchangers due to their thermal and corrosion resistance.

4. Turbine Components: The high-temperature strength of nickel clad materials makes them suitable for turbine blades and other components.

What Role Do Nickel Clad Plates Play in the Aerospace and Defense Industries?

1. Lightweight and High-Strength Properties

In aerospace and defense applications, materials must offer high strength-to-weight ratios. Nickel clad plates provide the necessary strength while minimizing weight, which is crucial for aircraft and military vehicles.

2. Resistance to Extreme Conditions

Aircraft and defense equipment are subjected to extreme temperatures and environmental conditions. Nickel clad materials maintain their performance under these stresses, ensuring reliability and safety .

3. Applications in Aerospace and Defense

Aircraft Components: Nickel clad plates are used in the construction of various aircraft parts, including structural components and engine parts.

4. Military Vehicles: The durability and strength of nickel clad materials make them suitable for armored vehicles and other defense equipment.

How Do Nickel Clad Plates Benefit the Electronics and Electrical Engineering Fields?

1. Electrical Conductivity and EMI Shielding

Nickel's excellent electrical conductivity makes nickel clad plates ideal for electronic applications. Additionally, they provide effective electromagnetic interference (EMI) shielding, protecting sensitive electronic components from external interference .

2. Corrosion Resistance for Longevity

Electronic components often require materials that resist corrosion to ensure long-term reliability. Nickel clad plates offer this protection, extending the lifespan of electronic devices.

3. Applications in Electronics and Electrical Engineering

Connectors and Terminals: Nickel clad materials are used in the manufacture of electrical connectors and terminals.

4. Circuit Boards: The EMI shielding properties of nickel clad plates make them suitable for use in circuit boards.

5. Battery Components: Nickel clad plates are employed in battery terminals and other components requiring corrosion resistance and conductivity.

What Are the Advantages of Nickel Clad Plates in the Marine Industry?

1. Superior Corrosion Resistance in Saltwater Environments

Marine environments are highly corrosive due to the presence of saltwater. Nickel clad plates offer exceptional resistance to seawater corrosion, making them ideal for marine applications .

2. Structural Strength for Marine Equipment

The combination of nickel's corrosion resistance and steel's strength ensures that marine equipment constructed with nickel clad plates can withstand the mechanical stresses of ocean operations.

3. Applications in the Marine Industry

Shipbuilding: Nickel clad plates are used in the construction of ship hulls and other structural components.

4. Offshore Platforms: These materials are employed in offshore oil and gas platforms for their durability and corrosion resistance.

5. Marine Hardware: Nickel clad materials are used in the manufacture of marine hardware such as valves, pumps, and piping systems.

How Do Nickel Clad Plates Contribute to the Medical and Pharmaceutical Industries?

1. Biocompatibility and Sterilization

Nickel clad materials are biocompatible, making them suitable for medical applications. They can also withstand sterilization processes, ensuring the safety and hygiene of medical equipment .

2. Corrosion Resistance in Chemical Environments

Pharmaceutical manufacturing involves the use of various chemicals. Nickel clad plates resist corrosion from these substances, ensuring the integrity of processing equipment.

3. Applications in Medical and Pharmaceutical Industries

Surgical Instruments: Nickel clad materials are used to manufacture surgical tools that require corrosion resistance and biocompatibility.

4. Pharmaceutical Equipment: Reactors, mixers, and other equipment in pharmaceutical manufacturing utilize nickel clad plates for their durability and resistance to chemical corrosion.

5. Medical Devices: Components of medical devices, such as implants and diagnostic equipment, benefit from the properties of nickel clad materials.

What Are the Cost Considerations When Using Nickel Clad Plates Compared to Stainless Steel?

1. Material Cost and Performance

While nickel clad plates may have a higher initial cost compared to stainless steel, their superior corrosion resistance and durability can lead to lower maintenance and replacement costs over time. This makes them a cost-effective choice for applications where longevity and reliability are critical.

2. Application-Specific Benefits

In environments where corrosion is a significant concern, the extended service life of nickel clad plates can offset the higher upfront investment. Additionally, their performance in high-temperature and chemically aggressive environments can lead to improved operational efficiency and safety.

Nickel-based alloy composite plates, or nickel clad plates, offer a unique combination of corrosion resistance, high-temperature performance, and structural strength. These properties make them indispensable across a wide range of industries, including chemical processing, oil and gas, power generation, aerospace, electronics, marine, and medical sectors. By understanding the specific advantages and applications of nickel clad plates, industries can make informed decisions to enhance the durability, safety, and efficiency of their operations.

Contact Us

For more information about nickel clad plates and how they can benefit your specific applications, please contact us:

Email: zh@baojiti.com.cn

Our team of experts is ready to assist you with your material selection and provide tailored solutions to meet your industrial needs.

YOU MAY LIKE

_1735019249058.webp)