How Is Tantalum Steel Clad Plate Made?

2025-07-07 17:05:48

What Is a Tantalum Steel Clad Pipe Plate?

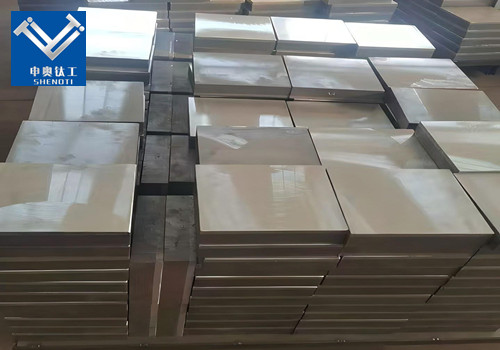

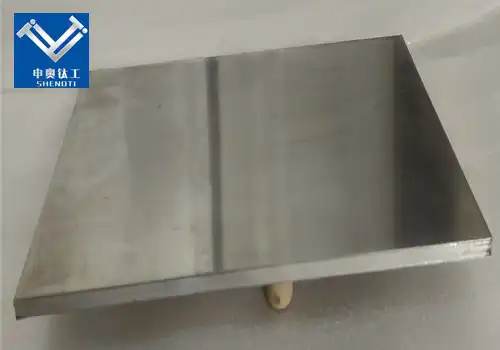

A tantalum steel clad pipe plate is a type of metal composite material made by bonding a layer of tantalum to a base of carbon steel or stainless steel. This combination leverages the exceptional corrosion resistance of tantalum with the mechanical strength, formability, and lower cost of steel.

Structure and Composition

Cladding Layer: Pure tantalum (Ta) or tantalum alloys such as Ta-2.5W.

Base Layer: Typically carbon steel (Q235, Q345) or stainless steel (304, 316L).

Bonding Method: Usually explosion bonding or hot rolling, followed by vacuum diffusion annealing.

This structure allows the final clad plate or pipe to resist strong acids such as hydrochloric acid, sulfuric acid, and nitric acid, even at high temperatures.

Why Choose Tantalum Steel Clad Pipe Plate?

The tantalum steel clad pipe plate is not just a solution—it’s a strategic advantage in harsh chemical processing environments.

1: Exceptional Corrosion Resistance

Tantalum is often referred to as a “noble metal” due to its near immunity to corrosion in most acids. It forms a stable oxide layer (Ta₂O₅) that resists:

Hydrochloric acid (HCl)

Sulfuric acid (H₂SO₄)

Nitric acid (HNO₃)

Aqua regia

Bromine and other halogens

2: Excellent Mechanical Properties

Thanks to the steel backing, these clad plates and pipes offer:

High tensile strength

Impact resistance

Pressure and thermal shock resistance

Easy fabrication and welding

3: Significant Cost Efficiency

Using pure tantalum for entire vessels or pipelines would be prohibitively expensive. The tantalum steel clad pipe plate reduces costs by up to 80%, while delivering similar corrosion resistance.

Applications of Tantalum Steel Clad Pipe Plate

1: Chemical Processing Industry

Reactors, heat exchangers, condensers, and pipeline systems used in:

Chlor-alkali production

Sulfuric acid towers

Nitric acid manufacturing

Organic and inorganic chemical synthesis

2: Pharmaceutical Manufacturing

Tantalum's biocompatibility and resistance to aggressive cleaning agents make it ideal for:

Sterilization equipment

Reactor vessels

Distillation towers

3: Aerospace and Defense

Corrosion-resistant structural components

Engine parts exposed to halogen environments

Nuclear fuel containment systems

4: Semiconductor and Electronics Industry

Etching tanks

High-purity chemical transport lines

Thin film deposition equipment

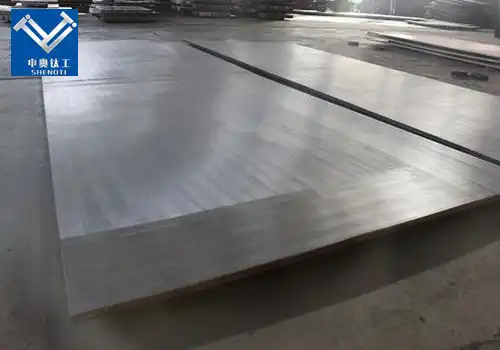

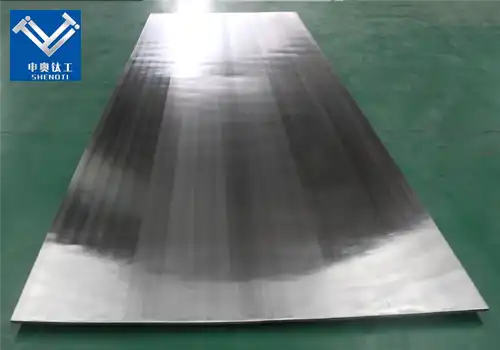

Manufacturing Process of Tantalum Steel Clad Pipe Plate

The performance of a tantalum steel clad pipe plate depends heavily on its manufacturing process. Several bonding technologies are used:

Explosion Bonding

This involves detonating explosives on a tantalum-steel sandwich under precisely controlled conditions, producing a solid-state metallurgical bond through high-energy impact. It’s ideal for bonding dissimilar metals with vastly different melting points.

How to Select the Right Tantalum Steel Clad Pipe Plate

1: Evaluate Corrosive Medium

Is the environment highly acidic? Are there halogens or oxidizers? Tantalum is excellent for all of these.

2: Consider Mechanical Load

If your application involves pressure or impact, the steel layer must be properly selected (e.g., Q345 for strength).

3: Choose the Right Cladding Thickness

Thicker tantalum layers offer better durability but increase cost. Optimize based on corrosion rate and life cycle.

Work With a Reliable Manufacturer

Ensure the supplier provides:

Explosion bonding or hot rolling expertise

Full traceability of raw materials

Third-party testing reports

Custom fabrication services

Industry Standards and Certifications

Most tantalum steel clad pipe plates comply with international standards, including:

ASTM B708 (for tantalum and tantalum alloy plate, sheet, and strip)

ASME SB-265

GB/T 8547-2021 (for clad metals)

ISO 9001 and ISO 14001 (manufacturer certifications)

Custom designs may also conform to pressure vessel codes such as ASME Section VIII or PED (Europe).

Frequently Asked Questions (FAQs)

1: What is the lifespan of a tantalum steel clad pipe plate?

Typically, more than 20 years in a corrosive industrial environment, depending on application and thickness.

2: Can the clad plates be welded or bent?

Yes. With appropriate techniques, tantalum steel clad materials can be bent, rolled, and welded—even into complex pipe elbows or tees.

3: Are there alternatives to tantalum?

Yes, but none offer the same performance in concentrated acid environments. Alternatives like zirconium, niobium, or titanium may be used but have limitations in oxidizing acids.

Choosing this advanced clad material ensures long-term reliability, reduced maintenance, and superior performance in the harshest conditions.

If you're looking to invest in high-performance materials for corrosive environments, the tantalum steel clad pipe plate should be your top consideration.

About Us

At Baoji ShenAo Metal Materials Co., Ltd., we specialize in the design, production, and customization of tantalum steel clad pipe plates and other non-ferrous clad metal solutions. With cutting-edge bonding technology and an ISO-certified quality system, we serve clients across chemical, aerospace, and pharmaceutical industries globally.

Website: shenaocladplate.com

Email: zh@baojiti.com.cn

Location: Baoji City, China’s Titanium Valley

Contact Us for a Free Consultation

Looking for a reliable supplier of tantalum steel clad pipe plates? We provide:

Custom sizes and thickness

Complete technical support

International shipping and after-sales service

Send your inquiry to zh@baojiti.com.cn and get expert guidance today!

YOU MAY LIKE

_1735019249058.webp)