Durable bonding ensures long-lasting performance.

High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

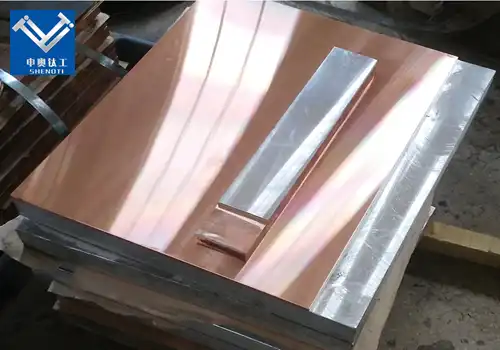

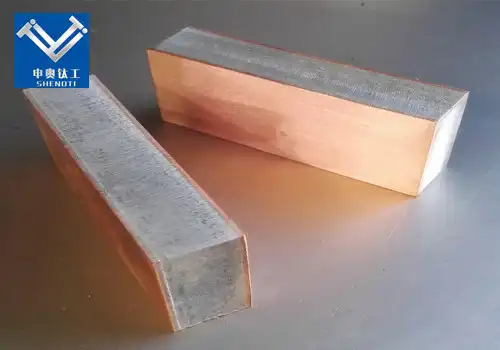

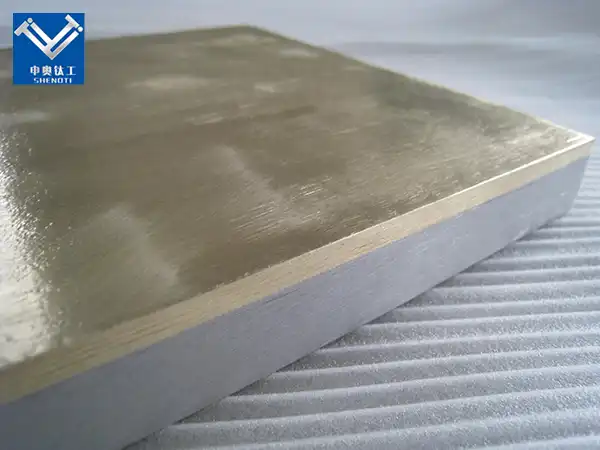

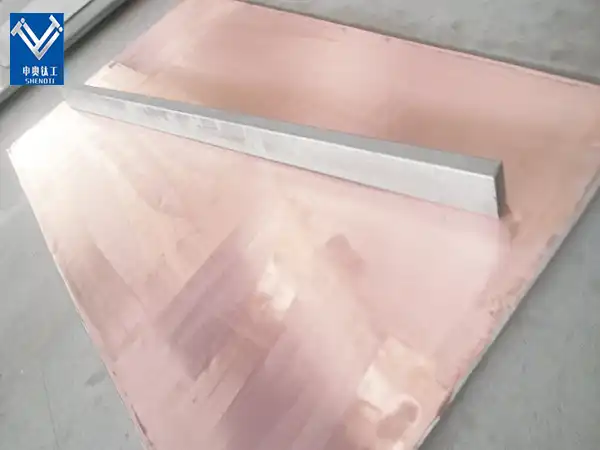

Introduction To 6061/T2 Aluminum Copper Clad Plate

An inventive composite material designed to satisfy the exacting specifications of sectors like electrical power, electronics, and environmental technology is the 6061/T2 aluminum copper clad plate. The remarkable conductivity and thermal performance of T2 copper are combined with the strength, resistance to corrosion, and lightweight nature of 6061 aluminum in this high-performance material. Because of its many uses, which include heat dissipation and effective power transmission, it is a popular choice for experts looking for sustainable and dependable materials.

Preparation process of 6061/T2 aluminum-copper clad plate

Depending on different application requirements, 6061/T2 aluminum-copper clad plate can be composited through a variety of processes, among which the more mature technologies include:

1. Explosive welding technology

Explosive welding is a technology that uses the high energy released instantly by the explosion of explosives to form a metallurgical bond between metal materials under high-speed collision. This method has the characteristics of high bonding strength and dense bonding interface, and is suitable for the manufacture of large-area composite plates.

2. Rolling composite process

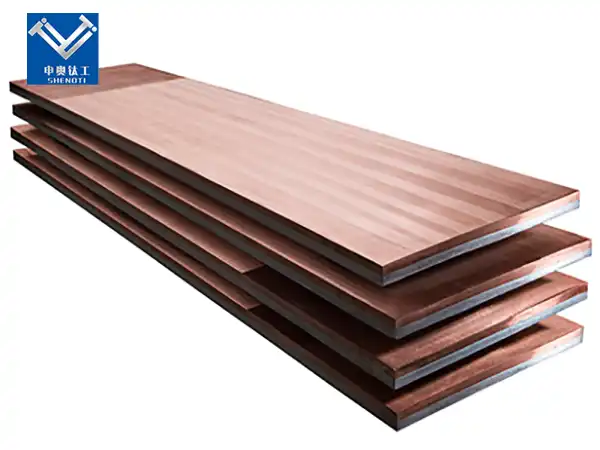

By rolling 6061 aluminum plate and T2 copper plate for multiple times under high temperature and high pressure, the physical connection and diffusion bonding of the two metals are achieved. This method can greatly improve the uniformity and flatness of the composite layer and is suitable for mass production.

3. Vacuum diffusion welding

Heating and applying pressure under vacuum conditions causes atomic-level diffusion bonding between 6061 and T2 at the contact interface. This process is suitable for the composite of precision parts with high requirements for the purity of the bonding interface.

Comparative advantages of 6061/T2 aluminum-copper clad plate and traditional copper-aluminum materials

|

Performance indicators |

6061/T2 aluminum-copper clad plate |

Pure copper plate |

Traditional aluminum alloy plate |

|

Density |

Medium |

High |

Low |

|

Electrical conductivity |

High |

Very high |

Medium |

|

Thermal conductivity |

High |

Very high |

Medium |

|

Strength and rigidity |

High |

Medium |

Medium |

|

Cost control |

Excellent |

High cost |

Low cost |

|

Processing performance |

Excellent |

General |

Excellent |

|

|

|

|

|

|

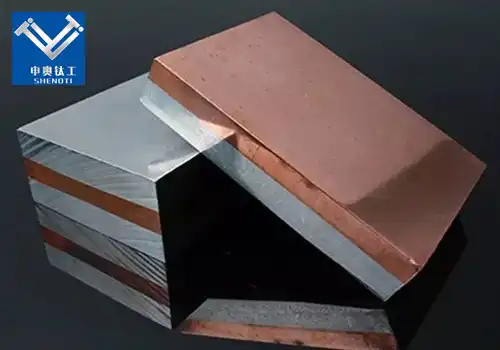

Key performance of 6061/T2 aluminum-copper composite board

1. Excellent electrical and thermal conductivity

Due to the high electrical conductivity (close to 59MS/m) and high thermal conductivity of T2 copper, 6061/T2 aluminum-copper composite board performs well in electrical and heat dissipation applications, which can significantly improve system efficiency.

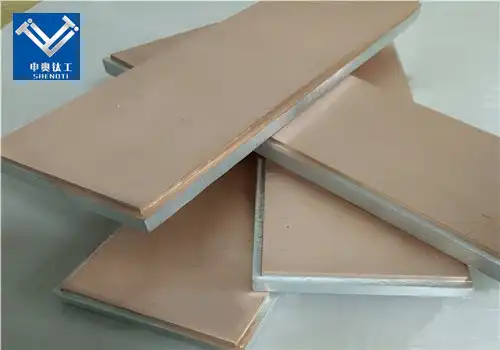

2. Lightweight and high-strength material

The low density of 6061 aluminum alloy (about 2.70g/cm³) reduces the weight of the overall composite board by more than 30% compared with pure copper board. At the same time, it has good strength and rigidity, which is convenient for lightweight structural design.

3. Excellent corrosion resistance

6061 alloy has good oxidation resistance, which is particularly suitable for long-term use in hot and humid environments to avoid failure of copper materials due to corrosion.

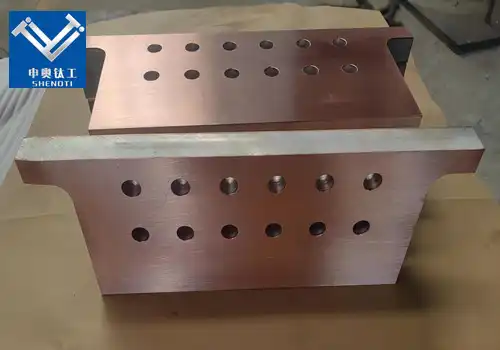

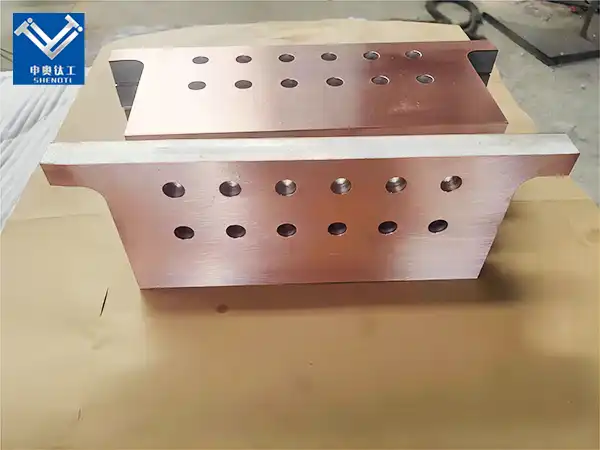

4. Good machinability and weldability

6061/T2 aluminum-copper composite board has good machinability, stamping, bending and other processing properties, which can meet the manufacturing needs of complex parts structures. At the same time, controllable welding can be achieved under proper treatment to meet the requirements of connection reliability.

Application fields of 6061/T2 aluminum-copper composite plate

1. Power and electronics industry

In high-conductivity demand occasions such as busbars, cable joints, and battery connectors, 6061/T2 aluminum-copper composite plates can not only ensure stable current transmission, but also reduce the overall quality of the system and improve energy utilization efficiency.

2. New energy vehicles

New energy vehicles have higher requirements for the conductivity, strength and lightweight of battery module connectors. 6061/T2 aluminum-copper composite plates just meet the multiple performance indicators of such electrical connection components.

3. Communications and 5G equipment

In high-frequency and high-speed scenarios such as 5G base stations and server cooling modules, copper-aluminum composite structures can provide excellent heat dissipation performance and structural support, effectively extending the service life of equipment.

4. Architecture and decoration

Using the lightweight beauty of 6061 aluminum and the color and antibacterial properties of T2 copper, 6061/T2 aluminum-copper composite plates are used in high-end building exterior walls, door and window decorative panels, etc., combining structural functionality and decorativeness.

The 6061/T2 aluminum-copper clad plate produced by Baoji Shenao Company has the following advantages

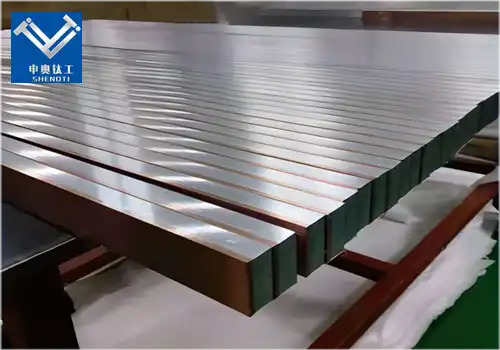

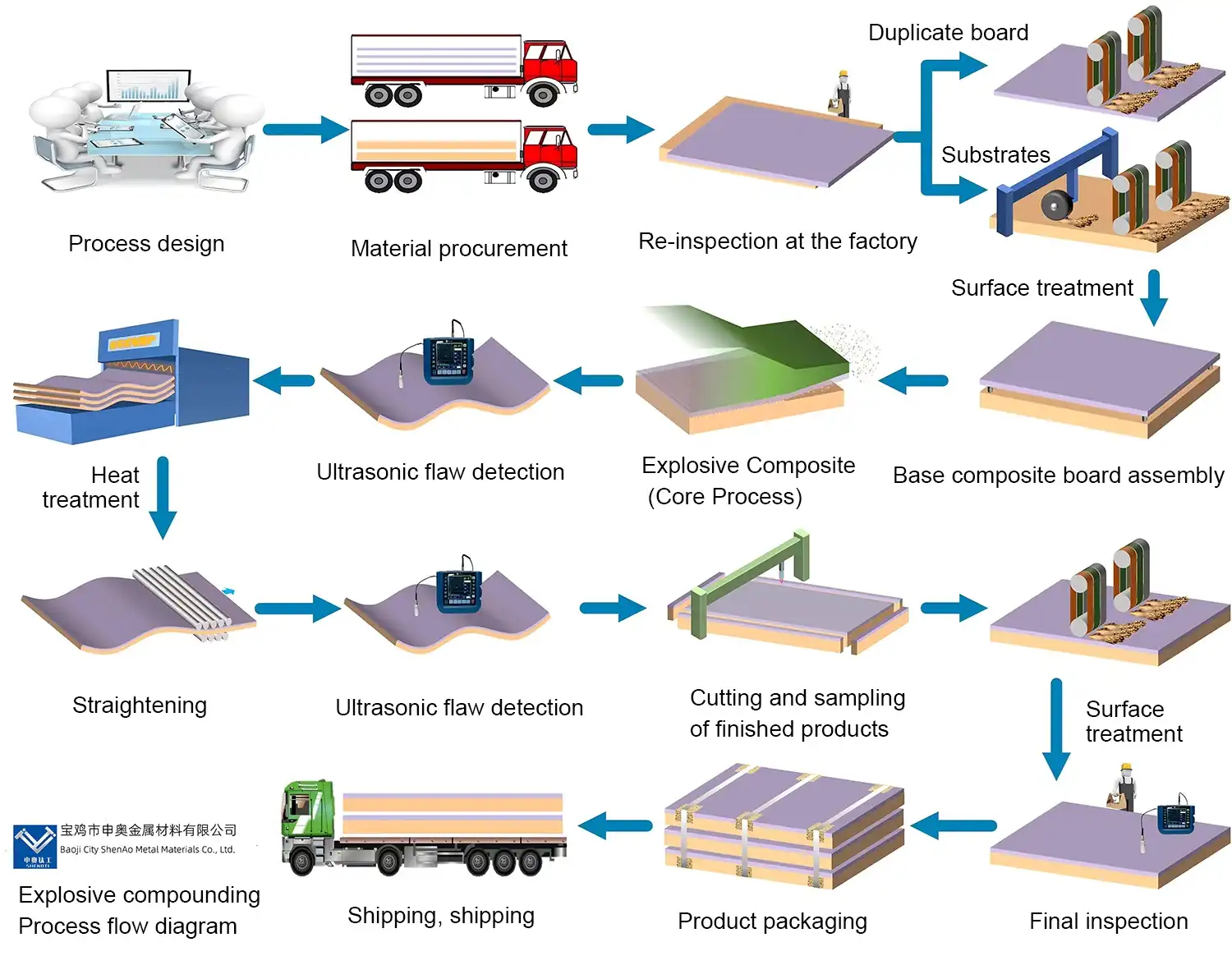

Mature composite process: such as explosion welding, explosion-rolling composite;

Interface bonding strength: interface shear strength is higher than the industry standard;

Reasonable composite ratio: copper layer thickness is uniform and meets the conductive design requirements;

Material consistency and testing standards: through ultrasonic, peeling test, conductive performance test and other tests;

Manufacturer qualifications and technical support: with mass production capabilities and technical service team, providing customized composite plate solutions.

|

|

|

|

|

|

|

Product production process

Why Choose Us

- Research and Innovation: With an experienced R&D team, Baoji City ShenAo Metal Materials Co., Ltd. continuously innovates to create advanced materials tailored to customer needs.

- Excellent Reputation: With 17 years of experience, we are recognized for delivering high-quality products and exceptional customer service.

- Striving for Excellence: Our strict production processes and quality management system ensure consistency, whether for small-scale testing or large-scale production.

- Customized Services: We provide bespoke solutions to meet diverse technical and application requirements.

- Timely Delivery and Support: Efficient logistics and customer-centric after-sales service ensure a seamless experience.

- OEM Services: We offer flexible manufacturing solutions to meet your unique specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

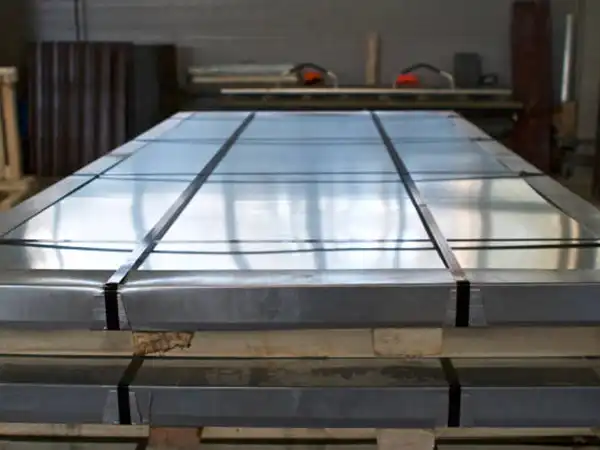

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q: What cladding ratios are available for the 6061/T2 aluminum copper clad plate?

A: We offer customizable ratios such as 70:30 or 60:40 to match specific application needs.

Q: Is the material suitable for marine environments?

A: Yes, its corrosion-resistant properties make it highly effective in marine applications.

Q: Can you provide samples for testing?

A: Absolutely! We provide samples to help you evaluate the product's suitability for your needs.

Contact Details

Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- E-Mail: zh@baojiti.com.cn

For inquiries or customized solutions, feel free to reach out to us today!

YOU MAY LIKE