High conductivity Inheriting the excellent conductive properties of copper

Lightweight Using the low density of aluminum to reduce weight

Cost-effectiveness Balancing performance and cost to provide economic solutions

Metallurgical bonding 100% metallurgical bonding to ensure material reliability

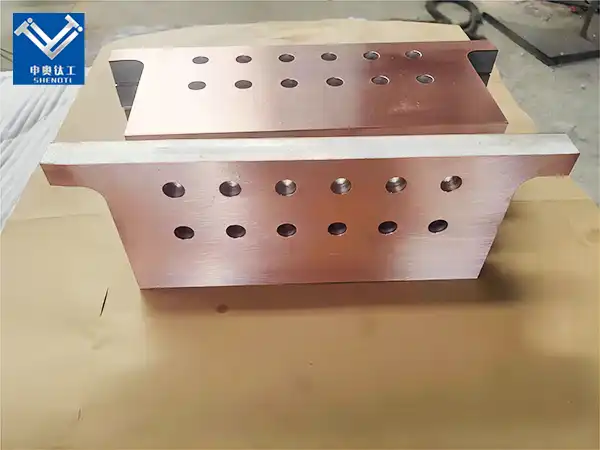

Introduction To TU2/5083 Copper Aluminum Clad Plate

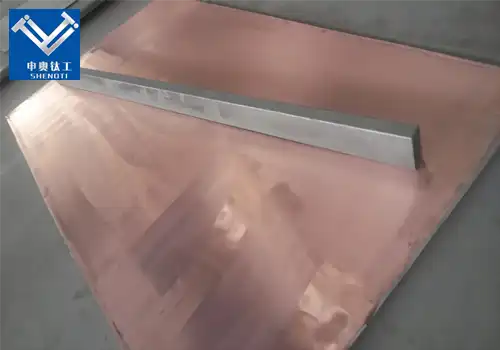

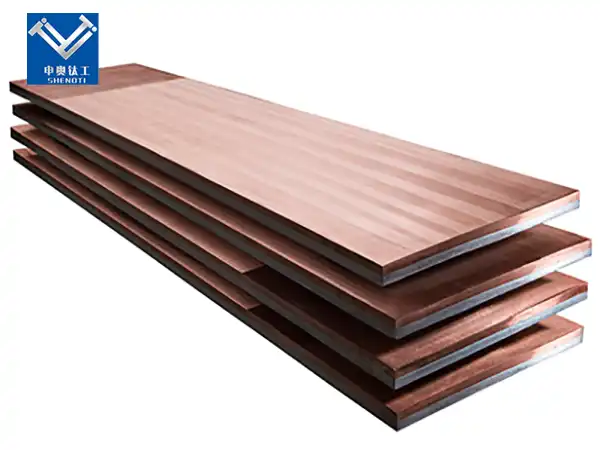

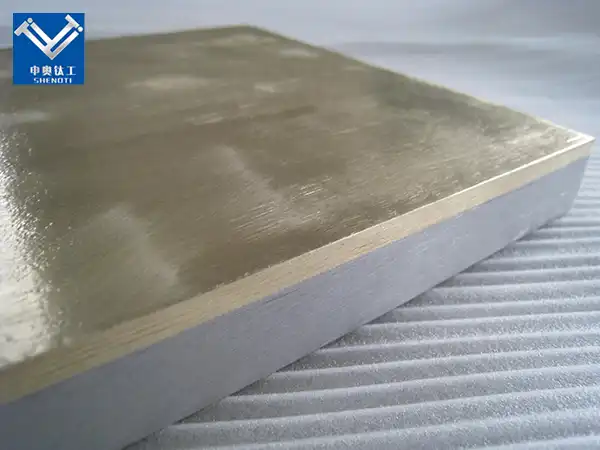

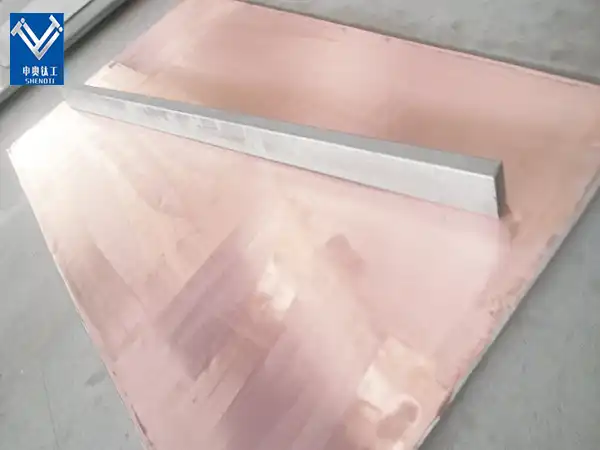

TU2/5083 copper aluminum clad plate is a bimetallic composite material made of high-purity copper (TU2) and aluminum alloy (5083) through explosion welding, rolling composite or detonation + rolling. TU2 copper has excellent electrical and thermal conductivity, while 5083 aluminum alloy is known for its good corrosion resistance, strength and weldability. The metallurgical combination of the two materials can not only achieve the complementarity of material properties, but also greatly reduce costs.

Technical Specifications

|

Parameter |

TU2 (Copper Layer) |

5083 (Aluminum Layer) |

|

Purity |

≥99.9% |

≥96% |

|

Thickness Range |

1–10 mm |

2–100 mm |

|

Width |

1000 mm |

|

|

Length |

2000 mm |

|

|

Bonding Strength |

≥110 MPa |

|

|

Electrical Conductivity |

≥85%-97% |

|

|

Corrosion Resistance |

Stable |

|

|

Operating Temperature Range |

-269°C |

|

These specifications ensure that the product delivers reliable performance across various industrial applications.

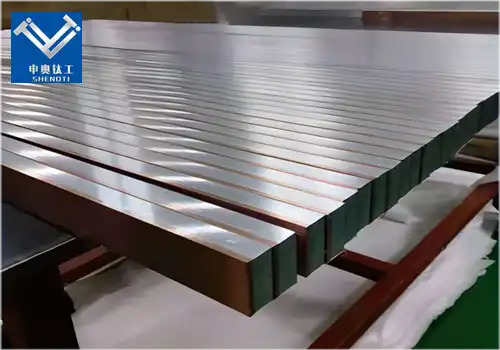

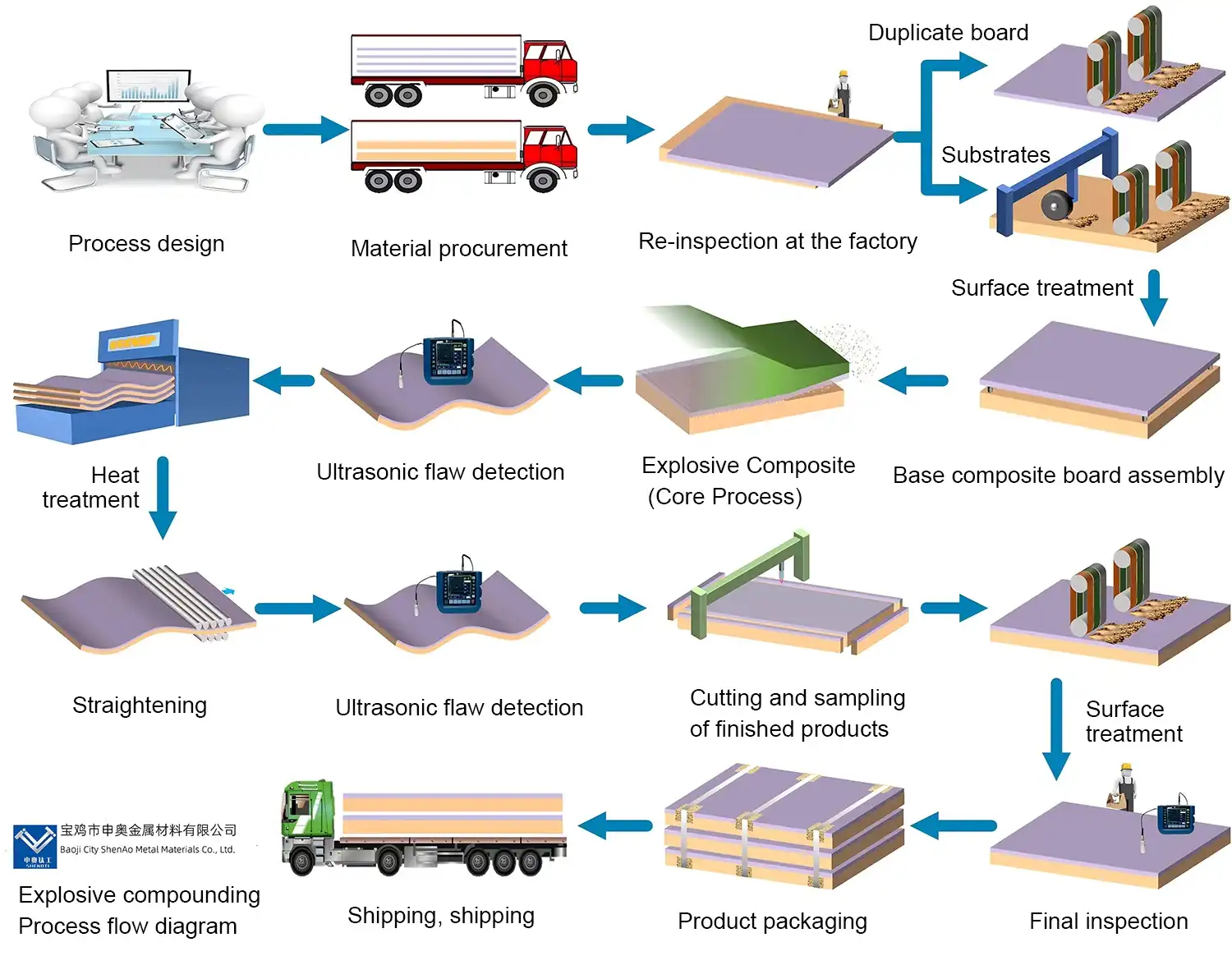

Production process of TU2/5083 copper-aluminum clad plate

1. Explosive welding technology

Explosive welding is a process that uses the high-energy shock wave generated by the explosion of explosives to achieve metallurgical bonding of two metal materials. This method can break through the limitations of "difficult-to-weld metals" in traditional welding and achieve a strong bond between copper and aluminum.

Advantages:

High bonding strength;

Dense bonding interface to avoid inclusions and cracks;

Can be used for large-area composites.

2. Rolling composite method

Hot rolling or cold rolling is used to press copper and aluminum to form a composite plate. The copper and aluminum surfaces are first treated (deoxidation, roughening, etc.) to improve the bonding strength.

Advantages:

Relatively low cost;

Suitable for continuous and batch production;

Can achieve thinner composite layer control.

3. Detonation + rolling composite

Combining explosive welding with rolling technology, after obtaining a preliminary bond, the interface quality and composite uniformity are further improved by rolling. This process is widely used in the preparation of high-performance TU2/5083 copper-aluminum composite plates.

|

|

|

|

|

|

Advantages of TU2/5083 copper-aluminum clad plate1. Excellent thermal and electrical conductivity

1. Excellent thermal and electrical conductivity

The TU2 copper layer is on the surface or functional area of the composite plate, with excellent electrical and thermal conductivity, and is suitable for scenes with dense current or high thermal conductivity requirements, such as power connection plates, heat dissipation modules, etc.

2. Good corrosion resistance and structural strength

The 5083 aluminum alloy layer has good structural support and corrosion resistance, and is suitable for applications in corrosive environments such as oceans and chemicals. For example, the aluminum layer effectively reduces the overall weight while increasing the corrosion resistance life.

3. Reduce costs

Compared with pure copper materials, the use of TU2/5083 copper-aluminum clad plates can greatly reduce the amount of copper materials and reduce the overall cost, which is suitable for large-scale application scenarios.

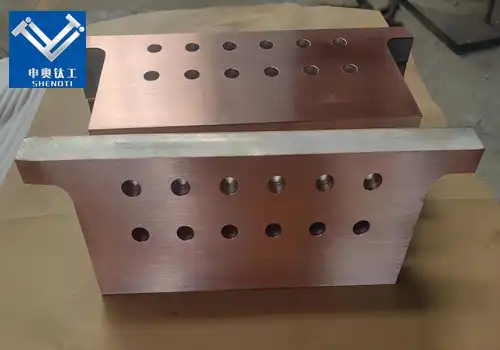

4. Good processing performance

The copper-aluminum composite material has good formability and can be subjected to mechanical processing such as shearing, stamping, and bending. It is also suitable for welding (especially aluminum end welding) to meet the needs of complex component manufacturing

Application fields of TU2/5083 copper-aluminum clad plate

1. Power industry

Busbar, cable connection terminal, busbar

Conductor material of high-frequency transformer

Thermal conductive heat sink of power distribution equipment

The copper layer provides a low-resistance channel, and the aluminum layer reduces the overall weight and cost, replacing the preferred material of the all-copper solution.

2. Shipbuilding and marine engineering

5083 aluminum alloy is the representative material of marine aluminum. After being compounded with TU2 copper, it is used in hull grounding system, corrosion-resistant electrical connection plate, etc., with both anti-corrosion and conductive properties.

3. New energy equipment

Photovoltaic junction box, inverter heat sink

Power battery housing guide plate

Hydrogen energy/fuel cell thermal conductive structural parts

Copper-aluminum composite materials are playing an increasingly important role in the lightweight and energy efficiency management of new energy vehicles.

4. Heat exchange system

Using the high thermal conductivity of copper and the corrosion resistance and light weight of aluminum, TU2/5083 copper-aluminum composite plates are widely used in heat exchangers, air conditioners, refrigeration equipment and other systems to improve heat exchange efficiency.

|

|

|

|

|

|

|

Product production process

Why Choose Us?

- Research and Innovation: Our experienced R&D team constantly pushes the boundaries of material science, ensuring products like the TU2/5083 clad plate remain at the forefront of technological innovation.

- Excellent Reputation: With over 17 years of industry expertise, Baoji City ShenAo Metal Materials Co., Ltd. has established a trusted name for quality and reliability.

- Striving for Excellence: We maintain strict quality controls and advanced manufacturing processes, ensuring our products meet or exceed customer expectations consistently.

- Customized Product Services: We tailor our clad plates to your unique specifications, ensuring optimal performance for your application.

- Timely Delivery and Reliable Support: Our streamlined logistics and dedicated after-sales team ensure fast delivery and prompt issue resolution.

- OEM Services: Comprehensive manufacturing solutions designed to meet global standards.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

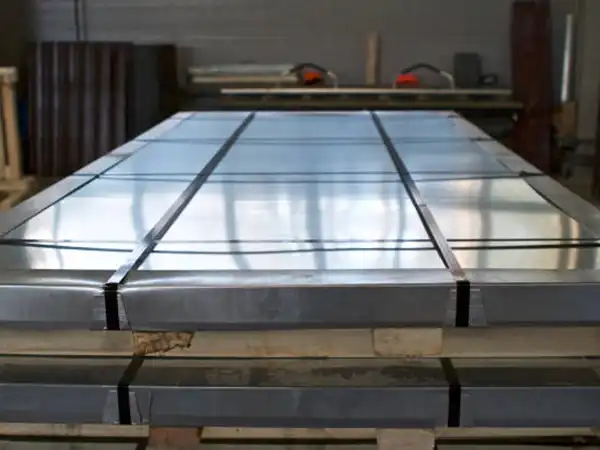

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q: What is the bonding process for the TU2/5083 clad plate?

A: We use explosive welding technology to achieve a seamless and robust bond between copper and aluminum layers.

Q: Can I customize the plate dimensions?

A: Yes, we offer customization for length, width, and thickness to suit specific project needs.

Q: What industries is this product best suited for?

A: The TU2/5083 Copper Aluminum Clad Plate is ideal for electrical, marine, chemical, and environmental applications.

Q: How can I ensure the product meets my quality standards?

A: Every product undergoes stringent testing and adheres to international quality certifications.

Contact Us

We’re here to assist you with all your inquiries and project requirements.

Company Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: 18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

For tailored solutions and exceptional service, reach out to us today.

YOU MAY LIKE