High strength and durability for demanding applications.

Excellent thermal and electrical conductivity performance.

Customizable sizes to suit specific project needs.

Reliable bonding ensures long-lasting structural integrity.

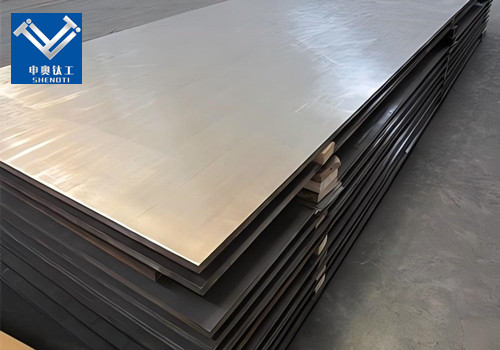

304 Stainless Steel Composite Plate: Durable, Versatile, and High-Performance

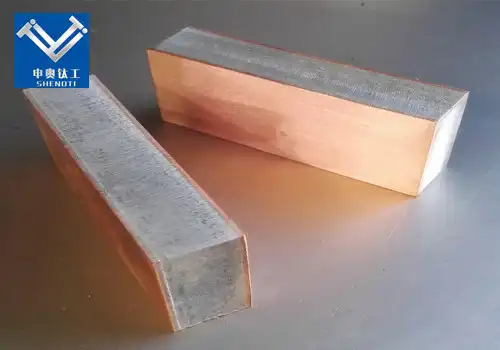

The 304 stainless steel composite plate is a highly versatile material used in various industrial applications due to its exceptional combination of durability, corrosion resistance, and structural integrity. At Baoji City ShenAo Metal Materials Co., Ltd., we manufacture these plates using advanced techniques like explosive welding to bond stainless steel with other metals, creating a strong, corrosion-resistant composite that meets the needs of industries such as chemical, energy, marine, electrical, and environmental protection.

Our 304 stainless steel composite plates are designed to offer enhanced performance in challenging environments, ensuring long-lasting service life and stability. Whether you're involved in chemical processing, power generation, or wastewater treatment, our products deliver the reliability you need for efficient and sustainable operations.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | 304 Stainless Steel Composite |

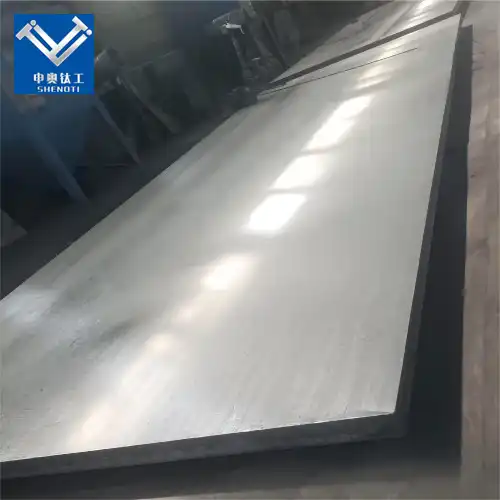

| Thickness | 2 mm - 50 mm |

| Width | 100 mm - 3000 mm |

| Length | Customizable |

| Bonding Technology | Explosive Welding |

| Hardness | 170 HB (approx.) |

| Tensile Strength | 500 MPa |

| Yield Strength | 215 MPa |

| Elongation | 40% |

| Corrosion Resistance | High (Resistant to most acids and salts) |

| Thermal Conductivity | 16 W/m·K |

| Electrical Conductivity | 2.0 x 10^6 S/m |

| Service Temperature | -196°C to 800°C |

|

|

|

Key Advantages of 304 Stainless Steel Composite Plate

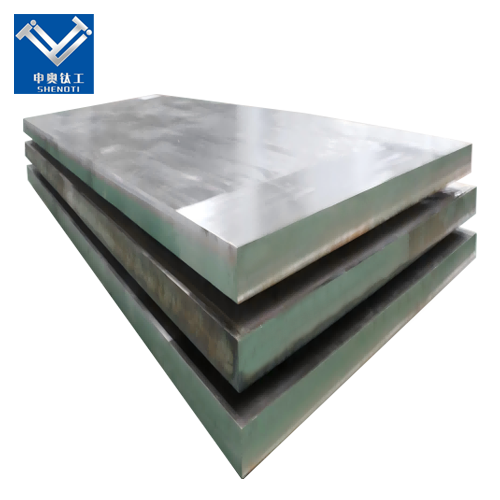

- Enhanced Durability: Combines corrosion resistance of stainless steel with structural strength of the base metal.

- Cost Efficiency: Offers a cost-effective alternative to solid stainless steel sheets.

- Versatility: Available in various thicknesses, widths, and lengths to meet project requirements.

- Ease of Fabrication: Compatible with cutting, welding, bending, and polishing processes.

- Aesthetic Appeal: Stainless steel surface provides a modern, high-quality finish for visible installations.

- Applications of 304 Stainless Steel Composite Plate

Applications of 304 Stainless Steel Composite Plate

1. Chemical and Petrochemical Industry

Used for tanks, pipelines, and reactors, the 304 stainless steel composite plate withstands aggressive chemicals and high temperatures, ensuring long-term performance in hazardous environments.

2. Construction and Architecture

Architects and engineers utilize these plates for façade cladding, roofing, and decorative panels. The combination of strength and visual appeal makes it ideal for modern buildings and large-scale infrastructure.

3. Food and Pharmaceutical Industry

Hygienic properties and corrosion resistance make 304 stainless steel composite plates suitable for food processing equipment, storage tanks, and pharmaceutical machinery.

4. Energy and Marine Applications

In power plants, offshore platforms, and marine equipment, these plates resist corrosion from seawater and extreme environmental conditions, ensuring longevity and reliability.

Case 304 Stainless Steel Composite Plate Industrial Storage Tanks

A chemical plant required storage tanks capable of resisting strong acids while remaining cost-efficient. By using 304 stainless steel composite plates with carbon steel backing, the plant achieved excellent corrosion resistance on the interior while reducing material costs. Over five years of operation, the tanks demonstrated no significant wear, confirming the reliability of composite plates in industrial applications.

|

|

|

|

|

|

|

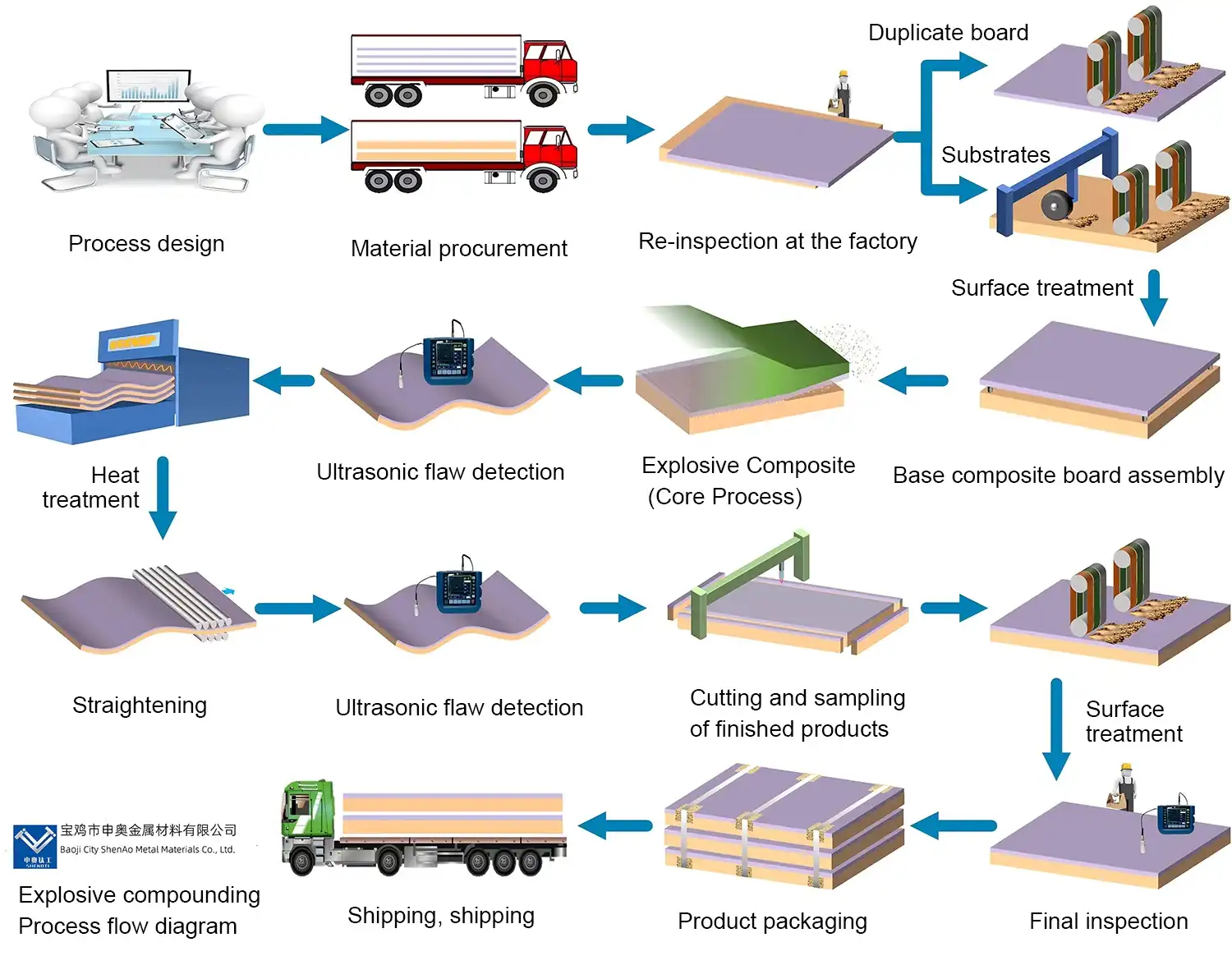

Product production process

Why Choose Us?

Our Advantages

-

Research and Innovation

Baoji City ShenAo Metal Materials Co., Ltd. is committed to continuous improvement and innovation. Our experienced R&D team works closely with clients to develop new processes and applications, ensuring the highest quality products tailored to your specific needs. -

Excellent Reputation

With over 17 years of experience, we have built a solid reputation for delivering high-quality products and reliable customer service. Our customers trust the Olympic Bid Titanium brand for its consistent performance and exceptional quality. -

Striving for Excellence

Our dedication to excellence is reflected in our strict production processes and comprehensive quality management system. From small batch testing to large-scale production, we ensure timely delivery and superior product quality. -

Customized Product Services

We offer customized solutions based on specific customer needs. Whether you need unique specifications or specialized titanium anodes, our flexible approach ensures that we meet your exact requirements. -

Timely Delivery & Worry-Free After-Sales Service

We understand the importance of meeting deadlines. Our commitment to fast delivery and comprehensive after-sales support ensures you can rely on us for all your product needs. -

OEM Services

We offer OEM services, allowing you to receive products tailored to your brand and technical specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What is the lead time for a custom 304 stainless steel composite plate?

Lead times typically range from 2 to 4 weeks, depending on the order size and customization requirements.

2. Can I order smaller quantities of the composite plates?

Yes, we offer flexible order quantities, including small batch orders, to accommodate your specific project needs.

3. How do I ensure the right specifications for my project?

Our experienced technical team is available to assist with material selection, ensuring the composite plate meets your performance and design requirements.

4. Are the 304 stainless steel composite plates suitable for marine environments?

Yes, our composite plates have excellent resistance to seawater corrosion, making them perfect for marine applications.

Contact Details

If you're interested in learning more or placing an order, please get in touch with us:

- Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- E-mail: zh@baojiti.com.cn

We look forward to helping you with your metal composite needs!

This page has been crafted to meet the needs of our target audience in industries such as energy, chemicals, marine, and electrical. With a focus on the 304 stainless steel composite plate, we've included key product specifications, features, applications, and frequently asked questions to drive engagement and improve SEO performance.