Is Copper Clad Aluminum Plate Reliable for High-Current Applications?

2025-06-19 17:15:29

Discover the reliability of copper clad aluminum plates in high-current applications. Learn about performance, advantages, FAQs, and industry insights. Contact us today for technical support and custom solutions.

Introduction: Meeting High-Current Demands with Composite Materials

In the era of rapid electrification, the demand for efficient, lightweight, and cost-effective conductive materials has surged. One standout solution is the copper clad aluminum plate (CCA plate), which combines the high conductivity of copper with the low weight and cost advantages of aluminum.

But how reliable is it under high-current conditions such as in power distribution, EV battery buses, or industrial electrical cabinets? Let’s explore the science and practical performance behind this versatile material.

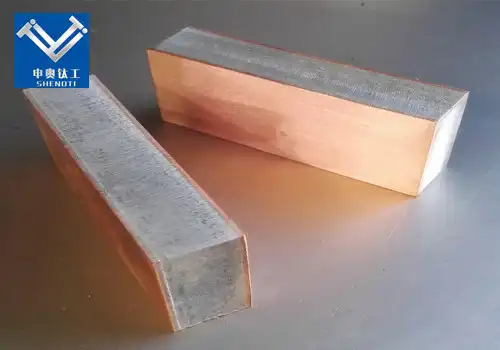

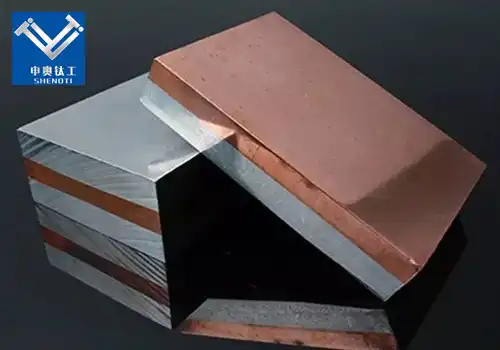

What is a Copper Clad Aluminum Plate?

A copper clad aluminum plate is a bimetal composite material made by explosion bonding, hot rolling, or explosive welding, where a thin copper layer is metallurgically bonded to an aluminum substrate. This design aims to offer:

High electrical conductivity

Reduced material cost

Lighter weight for structural applications

Enhanced surface solderability

How Does Copper Clad Aluminum Perform Under High Current?

Electrical Conductivity Comparison

Material Conductivity (% IACS)

Pure Copper (Cu) 100%

Aluminum (Al) ~61%

CCA Plate (Cu-Al) ~75–85% (Varies by Cu ratio)

CCA plates offer significantly improved conductivity over pure aluminum while reducing the cost and weight compared to solid copper.

Technical Specifications of Copper Clad Aluminum Plate

|

Item |

Specification |

Remarks |

|

Product Type |

Copper Clad Aluminum Plate (Cu-Al-Cu optional) |

Single or multi-layer options |

|

Bonding Method |

Explosion Bonding / Hot Rolling |

Strong metallurgical bond |

|

Standard Thickness |

1 mm – 50 mm |

Customizable on request |

|

Copper Layer Thickness |

0.5 mm – 5 mm (each side) |

Single or double sided |

|

Aluminum Core Grade |

1050, 1060, 3003, 6061, etc. |

Based on conductivity or strength requirement |

|

Copper Grade |

T2 (C11000), C10200 |

≥ 99.9% purity |

|

Electrical Conductivity |

≥ 75% IACS (depending on Cu content) |

Higher than pure Al, slightly lower than pure Cu |

|

Tensile Strength |

≥ 130 MPa |

ASTM B898 standard |

|

Peeling Strength (Cu-Al) |

≥ 12 N/mm |

Strong interfacial bonding |

|

Thermal Conductivity |

180 – 300 W/m·K |

Good heat dissipation |

|

Surface Treatment |

Bright, Brushed, Nickel-plated, Tin-plated |

Optional per application |

|

Corrosion Resistance |

Excellent (passivation or coated) |

Salt spray > 500 hours (custom) |

|

Weldability |

Excellent (resistance welding, ultrasonic, etc.) |

Especially suited for battery and EV use |

|

Dimension Tolerance |

±0.05 mm – ±0.2 mm |

Depending on thickness and process |

Thermal Performance and Heat Dissipation

CCA plates maintain stable temperature rise in high-current applications, thanks to the copper's superior thermal conductivity (~390 W/m·K). The aluminum core helps dissipate heat effectively across larger surface areas.

Mechanical Reliability and Fatigue Resistance

Modern manufacturing ensures strong metallurgical bonding, eliminating risks of delamination or galvanic corrosion under long-term current flow. CCA plates can also handle thermal cycling and vibration stress common in power electronics.

What Are the Advantages of Copper Clad Aluminum Plates in Electrical Systems?

Key Benefits

Weight savings: ~30–50% lighter than solid copper

Cost-effective: Copper usage is reduced by over 70%

Good weldability and brazing performance

Compatible with busbars, terminals, and connectors

Is copper clad aluminum better than pure aluminum in high current circuits?

Yes. CCA plates offer better conductivity, less resistance, and improved thermal stability compared to pure aluminum, making them ideal for high-current buses and cables.

Will copper clad aluminum overheat?

When properly sized and bonded, CCA plates exhibit excellent thermal behavior and do not overheat in rated high-current applications.

Can copper clad aluminum be used in EV battery connections?

Yes, many EV manufacturers use CCA plates for battery interconnects and busbars due to weight and cost advantages, while meeting safety and performance standards.

How long does a copper clad aluminum plate last?

When manufactured to international standards (e.g., ASTM B898), CCA plates have long service life with minimal corrosion and fatigue.

Real-World Applications of Copper Clad Aluminum in High Current Environments

Electric vehicle (EV) battery packs and modules

Power distribution panels and busbars

Electrical substations and switchgears

Photovoltaic (solar) energy systems

Aerospace and marine electrical systems

Contact Us for Technical Consultation or Orders

Are you exploring copper clad aluminum plates for your high-current projects? Our technical experts are here to help you with:

✅ Product selection guidance

✅ Custom specifications (thickness, width, Cu/Al ratio)

✅ Fast delivery from stock or production

✅ OEM & ODM cooperation

Email us: zh@baojiti.com.cn

Visit our website: www.shenaocladplate.com

Call us: +86-18729731603