Electrochemical Technology is Making Further Efforts: Baoji Shenao Titanium Anode Helps Green Industrial Wastewater Treatment

2025-06-20 16:32:17

Electrochemical Technology is Making Further Efforts: Baoji Shenao Titanium Anode Helps Green Industrial Wastewater Treatment

Discover how Baoji Shenao’s titanium anode technology is revolutionizing industrial wastewater treatment. Learn how eco-friendly electrochemical methods are boosting sustainability and performance in heavy industries.

The Challenge of Industrial Wastewater Treatment

Industrial wastewater, often containing persistent organic pollutants, heavy metals, and toxic chemicals, has become a major environmental concern worldwide. Conventional chemical or biological treatments frequently struggle to meet emission standards and sustainable development goals.

Environmental Impact of Untreated Wastewater

Contamination of soil and groundwater

Harm to aquatic ecosystems

High costs of remediation

Regulatory penalties and brand damage

This drives the urgent need for more green, efficient, and durable solutions—and that’s where titanium anode electrochemical technology comes in.

What Makes Titanium Anodes Ideal for Electrochemical Treatment?

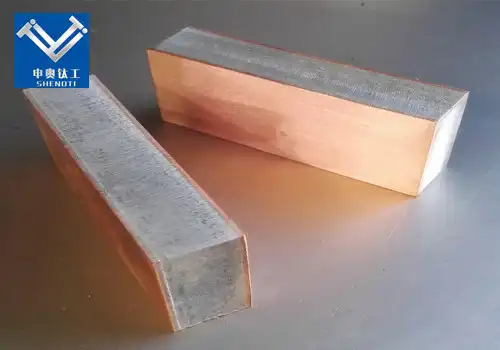

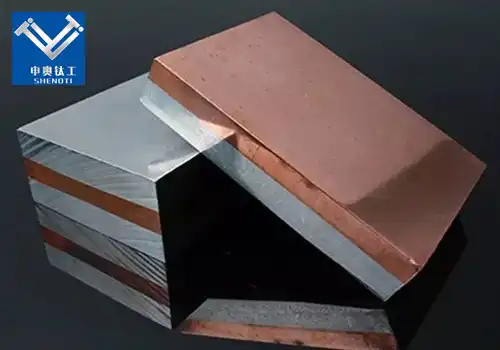

Titanium anodes are at the core of Electrochemical Oxidation (EO) and Electrocoagulation (EC) methods for industrial wastewater. Baoji Shenao’s titanium anodes are coated with noble metal oxides like IrO₂, RuO₂, or mixed metal oxides (MMO), offering a host of benefits:

Advantages of Titanium Anodes

High corrosion resistance in acidic and alkaline conditions

Long service life in continuous treatment systems

Low overpotential for oxygen and chlorine evolution

Uniform current distribution, ensuring stable performance

Eco-friendly, no chemical additives required

These properties make them ideal for industries such as electroplating, mining, chemical processing, dye production, and electronic wastewater treatment.

Baoji Shenao: Leading Supplier of Titanium Anodes in China

With over a decade of experience, Baoji Shenao Metal Materials Co., Ltd. has established itself as a pioneer in non-ferrous metal innovation. Located in the “Titanium Valley of China,” we provide titanium anodes customized for industrial needs.

Why Choose Shenao Titanium Anodes?

In-house R&D and production

ISO-certified quality system

Custom sizes, shapes, and coating formulas

Fast delivery and global shipping

Excellent technical support

How Baoji Shenao Ensures Quality and Efficiency

Advanced Coating Technology for Longer Service Life

Baoji Shenao titanium anodes are coated with proprietary DSA (dimensionally stable anode) materials such as Ru-Ir, Ir-Ta, and Pt. This enhances the anode's conductivity and extends its service life significantly, reducing operational costs and environmental impact.

Customization for Targeted Industrial Needs

Whether your facility handles high-concentration chemical effluents or needs selective oxidation capabilities, Baoji Shenao offers tailored anode solutions to meet strict regulatory discharge standards. Our titanium anodes are widely used in:

Electroplating wastewater treatment

Dye and textile effluent purification

High-COD wastewater remediation

Pharmaceutical manufacturing water processing

Applications of Titanium Anodes in Industrial Wastewater Treatment

Electrochemical Oxidation (EO)

Degrades persistent organics (phenols, cyanides, dyes) via direct or indirect oxidation using titanium anodes.

Electrocoagulation (EC)

Removes suspended solids, heavy metals, and emulsified oil with minimal sludge generation.

Disinfection and Decolorization

Destroys bacteria and color-causing compounds without adding harmful chemicals to the effluent.

Titanium Anode FAQ

What is the role of titanium anodes in wastewater treatment?

Titanium anodes serve as the anode material in electrochemical processes, helping to oxidize and remove pollutants such as COD, BOD, phenols, and heavy metals without chemical additives.

How long does a titanium anode last?

Depending on coating type and operation conditions, Shenao’s MMO-coated titanium anodes typically last 3–7 years or longer under continuous operation.

What is the difference between MMO and platinum titanium anodes?

MMO anodes are more cost-effective and suitable for high-volume applications, while platinum-coated titanium anodes offer higher purity and are used in lab or niche industrial systems.

Are titanium anodes eco-friendly?

Yes. They reduce or eliminate the use of secondary chemicals, produce minimal sludge, and consume less energy compared to conventional treatment methods.

Contact Us

Email: zh@baojiti.com.cn

Phone: +86-18729731603

Website: www.shenaocladplate.com

Address: Baoji City, Shaanxi Province, China