Titanium anodizing is a critical process that enhances the continuity, erosion resistance, and aesthetic appeal of titanium products. This electrochemical process forms a defensive oxide subcaste on titanium shells, which not only increases the material's strength and resistance to harsh surroundings but also allows for a wide range of color variations through the use of different anodizing ways.

At Baoji City ShenAo Metal Accoutrements Co., Ltd., we specialize in furnishing high- quality titanium products that suffer the anodizing process to meet the specific conditions of our different clientele. With moxie in the titanium assiduity, our products are designed for diligence similar as chemical and energy, environmental protection, marine, and more.

Manufacturing Process of Titanium Anodizing

1: Surface Preparation

Proper cleaning and surface preparation are vital for uniform anodizing. The titanium surface is first degreased using alkaline or solvent cleaners to remove oil, dirt, and residues. This is followed by acid etching or pickling to remove the natural oxide film and activate the surface.

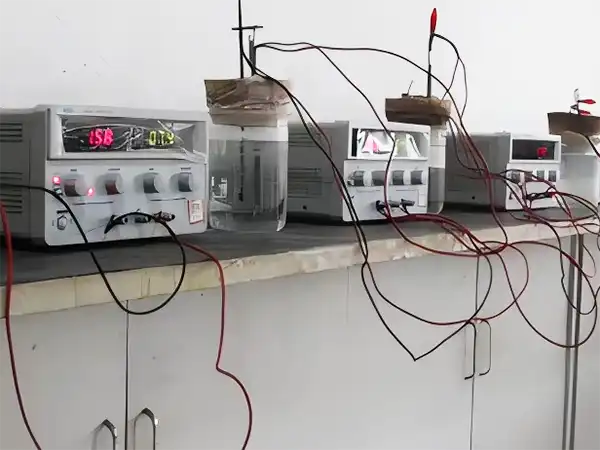

2: Electrolytic Oxidation

In this stage, the cleaned titanium parts are placed in an electrolytic bath. The power supply gradually increases voltage according to the desired color or oxide thickness. The anodizing duration and temperature are carefully controlled to ensure consistent quality.

3: Rinsing and Drying

After anodization, the components are thoroughly rinsed in deionized water to remove any chemical residues. They are then dried in a clean environment to prevent surface contamination.

4: Quality Inspection

To ensure top-quality results, anodized titanium parts undergo color verification, adhesion testing, and corrosion resistance tests. Advanced spectrophotometers and thickness gauges are often used for precision quality control.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Benefits of Titanium Anodizing

Enhanced corrosion resistance: The oxide layer acts as a barrier against harsh environments, especially in marine or chemical applications.

Improved wear resistance: Anodized titanium surfaces are harder and less prone to scratches.

Biocompatibility: Anodized titanium is safe for human implants and surgical tools.

Aesthetic variety: Multiple color options allow customization for branding or identification.

Electrical insulation: Certain anodized layers exhibit dielectric properties suitable for electronic components.

Applications of Titanium Anodizing Across Industries

1. Aerospace and Defense

In aerospace, titanium anodizing provides exceptional protection against oxidation, saltwater, and high-temperature environments. Components such as fasteners, brackets, and jet engine parts are commonly anodized to ensure long service life and lightweight performance.

2. Medical and Healthcare

In the medical field, titanium anodizing is a standard process for surgical tools, implants, and prosthetics. The oxide film enhances biocompatibility and allows easy sterilization. The color coding also helps surgeons quickly identify specific instruments or implant sizes.

3. Electronics and Semiconductor

Anodized titanium is widely used in electronic housings, connectors, and sensor components. Its non-conductive oxide layer provides insulation and prevents short-circuiting in sensitive devices.

4. Automotive and Racing

High-performance automotive parts—such as exhaust systems, suspension components, and fasteners—benefit from titanium anodizing due to its lightweight strength, corrosion resistance, and eye-catching finish.

5. Architecture and Interior Design

Designers use anodized titanium for decorative panels, sculptures, and façade elements. Its ability to maintain color without fading makes it ideal for long-term architectural applications.

Case Titanium Anodizing in Practice

1: Aerospace Fasteners

A leading aerospace manufacturer required lightweight yet corrosion-resistant fasteners for high-altitude applications. By applying titanium anodizing, the fasteners achieved a durable protective film that withstood extreme temperature fluctuations while maintaining precise torque characteristics.

2: Medical Implants

An orthopedic implant company adopted titanium anodizing to improve surface bioactivity and color-code implant sizes. The anodized layer enhanced tissue compatibility and facilitated safer identification during surgeries.

3: Electronics

In semiconductor production, titanium sensors anodized with a uniform oxide layer provided consistent performance and insulation across microelectronic systems.

|

|

|

|

|

|

|

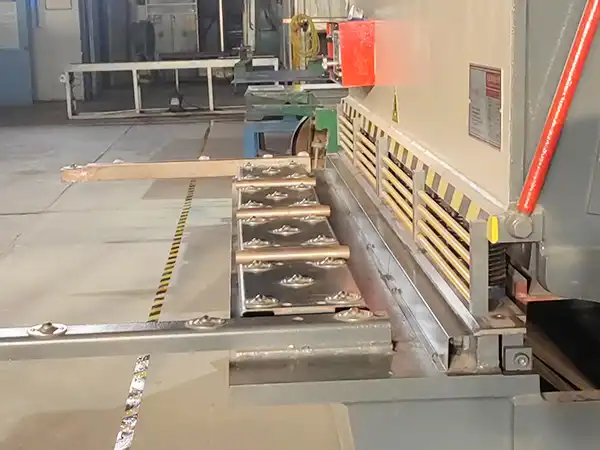

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

At Baoji City ShenAo Metal Materials Co., Ltd., we offer exceptional titanium anodizing products that meet the highest industry standards. Here’s why you should choose us for your titanium needs:

Research and Innovation

Our devoted R&D platoon focuses on nonstop invention, icing that we stay ahead of assiduity trends and offer products with superior performance. Whether it’s refining our anodizing ways or developing new operations for titanium, we're committed to furnishing slice- edge results to our guests.

Excellent Reputation

With over 17 times in the business, we've erected a strong character for quality and trustability. Our products and services have earned the trust of guests across colorful diligence, and we're proud to be a honored name in the titanium sector.

Striving for Excellence

We've meliorated our product processes to guarantee that every titanium product meets the loftiest norms. Our focus on quality control ensures harmonious results, whether for small batch testing or large- scale product.

Customized Product Services

Understanding that each client has unique conditions, we offer acclimatized results, including custom anodizing services, to meet specific specialized requirements. Our platoon works nearly with guests to insure that their exact specifications are met.

Timely Delivery, Worry-Free After-Sales Service

Our client-first approach means that we insure timely deliveries and offer excellent after- deals support. We aim to give hassle-free service, icing that your orders arrive on time and that you admit the necessary support whenever demanded.

OEM Services

We offer OEM services to feed to guests who bear tailored products or need to ingrain our titanium anodized products under their own markers.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What is our product?

It is an electrochemical process that forms a protective oxide layer on the surface of titanium, enhancing its corrosion resistance, surface hardness, and appearance.

2. How long does the anodized coating last?

The lifespan of the anodized layer depends on the application and environment. In harsh environments, the anodized layer can last for many years without significant degradation.

3. Can anodized titanium be colored?

Yes, the anodizing process can produce a range of colors, including gold, blue, purple, and more, by controlling the voltage during the process.

4. Is the product suitable for medical applications?

Yes, it is commonly used in medical implants and devices due to its biocompatibility and durability.

5. Can you provide customized anodizing services?

Yes, we offer tailored anodizing services to meet specific customer requirements, including custom colors and thickness levels.

Contact Us

For more information about Titanium anodizing or to place an order, contact us:

Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

We look forward to providing you with the highest-quality products and services.