Introduction to Anodize Titanium

Anodize titanium is a surface treatment technology that enhances the durability, functionality, and aesthetics of titanium. Unlike coatings or paints, anodizing modifies the titanium’s surface through an electrochemical process, forming a protective oxide layer that improves corrosion resistance, wear resistance, and visual appeal. This makes anodize titanium one of the most versatile solutions across aerospace, medical, jewelry, automotive, and architectural industries.

The unique characteristic of anodize titanium lies in its ability to produce vibrant, interference-based colors without dyes or pigments. By adjusting the anodizing voltage, titanium surfaces can achieve a wide spectrum of hues — from gold and bronze to purple, blue, and green — making anodize titanium both technically advanced and artistically appealing.

The Manufacturing Process of Anodize Titanium

1. Step-by-Step Guide to Anodizing Titanium

The process of anodize titanium involves precise control of parameters such as voltage, electrolyte composition, and immersion time.

2. Surface Preparation

Before anodizing, titanium surfaces undergo cleaning and polishing to remove impurities, grease, or oxides. This ensures consistent oxide layer growth.

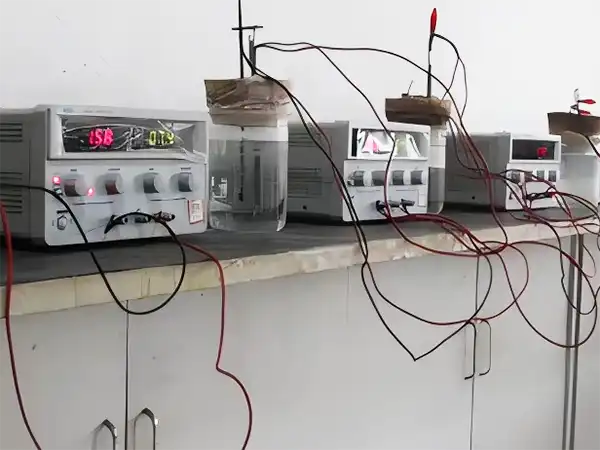

3. Electrolyte Bath Setup

Common electrolytes include phosphoric acid or sulfuric acid solutions. The titanium piece serves as the anode, while a cathode (often stainless steel) completes the circuit.

4. Application of Voltage

By adjusting voltage levels (10–120 V typically), different oxide thicknesses are achieved, directly influencing the final color of the anodized titanium.

5. Formation of Oxide Layer

Anodize titanium results in a stable, dense titanium dioxide (TiO₂) film that enhances both functionality and aesthetics.

6. Post-Treatment

Rinsing, sealing, and drying complete the process, producing a uniform anodized titanium surface ready for industrial or decorative use.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical Advantages of Anodize Titanium

1. Corrosion Resistance

Anodize titanium offers superior resistance to seawater, acids, and chlorides, making it ideal for marine and chemical applications.

2. Wear Resistance

The oxide layer provides enhanced surface hardness, reducing friction and extending product lifespan.

3. Biocompatibility

For medical devices and implants, anodize titanium ensures tissue compatibility, reducing rejection risks.

4. Customizable Aesthetics

Architectural and jewelry industries value anodized titanium for its broad range of durable, brilliant colors.

5. Eco-Friendly Process

Unlike painting or plating, anodize titanium does not involve hazardous materials, making it environmentally responsible.

Industrial Applications of Anodize Titanium

1: Aerospace Industry

In aerospace, anodize titanium components are used in structural parts, fasteners, and engine systems. The combination of lightweight properties and anodized corrosion resistance ensures reliability under extreme conditions.

2: Medical and Dental Devices

Surgical instruments, orthopedic implants, and dental implants rely on anodize titanium for its biocompatibility and sterilization resistance. Anodizing also allows color coding of implants for easy identification.

3: Automotive and Motorsport

Exhaust systems, suspension components, and fasteners are anodized to resist high-temperature oxidation and enhance mechanical performance. The colorful finish also adds visual appeal for premium vehicles.

4: Jewelry and Fashion Accessories

Anodize titanium has become a trend in rings, watches, and wearable art due to its hypoallergenic nature and vivid, customizable colors.

5: Electronics and Architecture

In electronics, anodized titanium improves electrical insulation. In architecture, anodized panels and cladding provide both durability and aesthetic variety.

Anodize Titanium Application Case

1: Medical Implants

Orthopedic manufacturers use anodize titanium for hip and knee

implants, ensuring durability and patient safety.

2: Aerospace Fasteners

Airbus and Boeing suppliers rely on anodized titanium fasteners to withstand high stress and corrosive environments.

3: Luxury Jewelry

Renowned designers incorporate anodize titanium rings and bracelets due to the wide spectrum of stable colors that never fade.

|

|

|

|

|

|

|

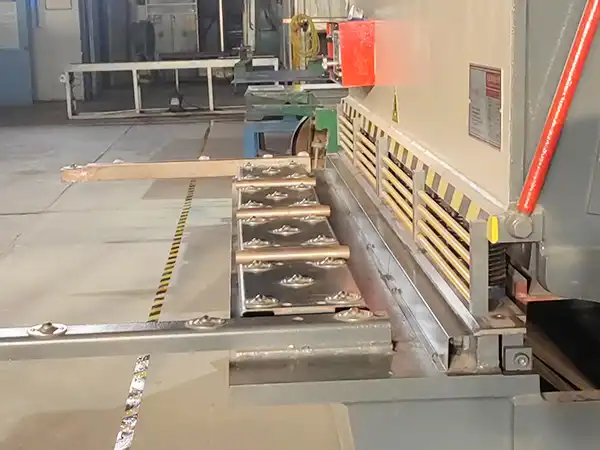

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

1. Research and Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., our experienced technical research and development team continuously works on exploring new processes and applications. We focus on innovation, ensuring that our products meet the evolving demands of our customers and lead to mutually beneficial results.

2. Excellent Reputation

With 17 years of industry experience, we have earned the trust and recognition of customers worldwide. Our commitment to high-quality products and reliable customer service has helped us build long-lasting relationships with our clients.

3. Striving for Excellence

We take pride in our stringent production processes and comprehensive quality management system, ensuring that each product adheres to the highest standards. Whether you require small batch testing or large-scale production, we ensure timely delivery and the consistent quality of our products.

4. Customized Product Services

We offer tailored solutions for various specifications of non-ferrous metal composite materials and titanium anodes, designed to meet the specific needs of our customers. Our ability to customize products ensures that we provide the best solutions for every application.

5. Timely Delivery, Worry-Free After-Sales Service

Our customer-centric approach ensures that we respond promptly to inquiries and provide exceptional after-sales support. We guarantee that our products meet the required specifications and perform reliably in all conditions.

6. OEM Services

We provide OEM services to meet the unique demands of customers, ensuring that each order is customized to their specific requirements, from material selection to production processes.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: What is anodized titanium used for?

Anodized titanium is used in a variety of industries, including aerospace, medical devices, marine, chemical processing, and environmental protection. Its enhanced corrosion resistance and biocompatibility make it a versatile material for demanding applications.

Q2: How is anodized titanium created?

Our product is created through an electrochemical process that increases the thickness of the titanium’s natural oxide layer. This process enhances its corrosion resistance and allows for the addition of various colors for aesthetic and functional purposes.

Q3: Can anodized titanium be used in seawater environments?

Yes, our products' superior corrosion resistance makes it an excellent choice for use in seawater environments, including marine equipment, desalination plants, and water treatment systems.

Q4: Is anodized titanium safe for medical use?

Absolutely. Titanium, including products, is known for its biocompatibility and non-toxic nature, making it ideal for medical implants, surgical instruments, and other medical applications.

Q5: How does the anodizing process affect the color of titanium?

The anodizing process can produce a variety of colors on titanium, including gold, blue, green, purple, and black. The color variations are a result of the thickness of the oxide layer, which affects how light interacts with the surface.

Contact Us

For more information or to place an order, feel free to contact us. We provide professional services and solutions tailored to your needs.

- Name: Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- E-mail: zh@baojiti.com.cn

We look forward to working with you and providing the highest-quality anodized titanium solutions for your business!

(1)_1734580705587.webp)