Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

SEO-Optimized Product Page for Titanium Anode for Electrocatalytic Oxidation Treatment

Product Introduction

Titanium anodes for electrocatalytic oxidation treatment are advanced, high-performance electrodes designed to enhance water treatment processes through efficient oxidation. Leveraging Baoji City ShenAo Metal Materials Co., Ltd.'s expertise in innovative metal processing and coating technology, these anodes are ideal for industries requiring effective and sustainable solutions for water purification, wastewater treatment, and industrial effluent management.

Manufactured using premium-grade titanium and coated with noble metals like iridium or ruthenium, our titanium anodes deliver exceptional corrosion resistance, conductivity, and long service life. Whether for chemical plants, environmental projects, or power facilities, these anodes are the ultimate choice for performance and reliability.

Technical Specifications

|

Feature

|

Details

|

|

Substrate

|

Titanium material Gr1, Gr2/TA1, TA2

|

|

Specifications:

|

Plate, tube, mesh, rod, wire, strip and other special-shaped specifications.

|

|

Coating composition

|

Ti、Ru、Ir、 Pt、Ta、Sn、Co

|

|

Coating conductivity

|

10~7Ω·m

|

|

Working current density

|

<2000A/㎡

|

|

Metal content

|

8~25g/㎡

|

|

Coating thickness

|

8~12㎛

|

|

Working temperature

|

<60℃

|

|

Working life

|

>5 years

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Features

-

Superior Corrosion Resistance

Titanium's natural resistance to corrosion combined with a durable noble metal coating ensures exceptional longevity, even in harsh chemical environments. -

High Conductivity

The optimized coating enhances electrical conductivity, making the anodes highly efficient in catalyzing oxidation reactions. -

Low Maintenance

Minimal degradation over time reduces the need for frequent replacements or maintenance, offering cost savings for long-term operations. -

Customizable Design

Tailored solutions for specific industrial applications, including size, coating material, and layer thickness. -

Eco-Friendly

Supports environmental sustainability by enabling efficient and chemical-free water treatment processes.

Applications

- Wastewater Treatment: Effective in removing pollutants and toxins from industrial effluents.

- Chemical Processing: Assists in electrochemical reactions for chemical manufacturing.

- Power Plants: Plays a vital role in cooling water treatment and recycling systems.

- Marine Industry: Suitable for seawater desalination and anti-fouling systems.

- Electrolysis Systems: Ideal for processes like electrowinning and chlor-alkali production.

|

|

|

|

|

|

|

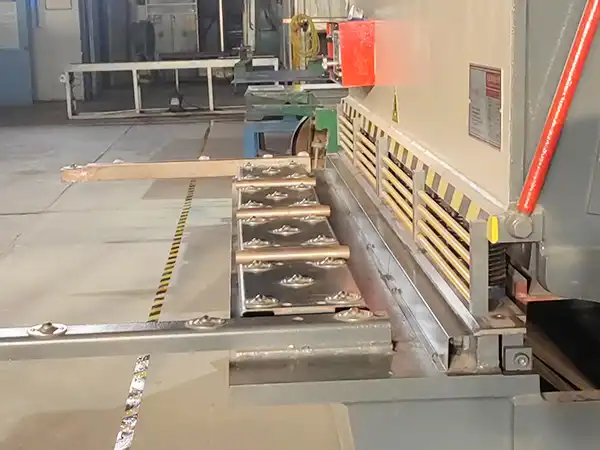

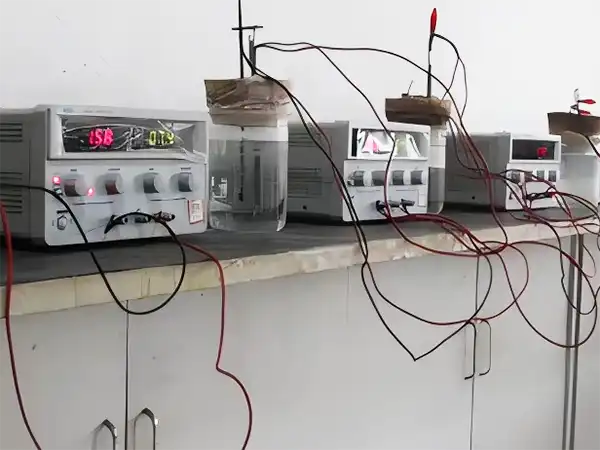

Product production process

|

|

|

|

|

|

|

|

|

|

Why Choose Us

1. Research and Innovation

Our dedicated R&D team continually develops cutting-edge solutions to meet diverse industrial needs, ensuring top-tier performance and innovation.

2. Excellent Reputation

With over 17 years of industry experience, Baoji City ShenAo Metal Materials Co., Ltd. has earned trust through consistent quality and reliable service.

3. Uncompromising Quality

We adhere to strict production standards and employ a comprehensive quality management system to deliver products that exceed expectations.

4. Customization Services

Tailored designs to fit the unique requirements of your project, ensuring seamless integration and optimal performance.

5. Timely Delivery and After-Sales Support

We prioritize customer satisfaction with on-time delivery and dedicated after-sales service to address any concerns promptly.

6. OEM Services

Collaborate with us to develop private-label products tailored to your specifications.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. How do I determine the right titanium anode for my application?

We provide consultation to help you select the best specifications and coatings for your specific needs.

2. Can these anodes handle extreme chemical environments?

Yes, our titanium anodes are designed to withstand a wide range of pH levels and high temperatures, ensuring durability in harsh environments.

3. Do you offer customization?

Absolutely! We tailor dimensions, coatings, and other parameters to meet your exact requirements.

4. What is the typical delivery time?

Delivery usually takes 3–4 weeks, depending on the order size and customization requirements.

Contact Us

We’re here to help you with the best solutions for your needs. Contact us today to learn more about our titanium anodes for electrocatalytic oxidation treatment.

Baoji City ShenAo Metal Materials Co., Ltd

- Address: Wenquan Village Industrial Park, High Tech Zone, Baoji City

- Contact: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Let us assist you in optimizing your industrial processes with premium titanium anodes.

This detailed and engaging product page is designed to attract search engine traffic, captivate your audience, and drive conversions while addressing customer pain points effectively.

YOU MAY LIKE

_1735543498027.webp)