Superior conductivity for efficient electrochemical reactions.

Durable ruthenium coating enhances electrode lifespan.

Excellent stability in aggressive environments.

Customizable sizes for various industrial applications.

In the field of electrochemistry, where precision, efficiency, and longevity are critical, the customized titanium electrode has become a core solution for industrial processes. Titanium electrodes, known for their corrosion resistance, mechanical strength, and electrochemical stability, are widely used in wastewater treatment, electroplating, chlor-alkali production, and hydrogen generation.

However, every industrial application presents unique challenges — from current density to electrolyte composition. That’s where the customized titanium electrode plays a vital role. By designing electrodes that match the client’s exact operating conditions, manufacturers like Baoji City ShenAo Metal Materials Co., Ltd. help enterprises achieve optimal performance, energy efficiency, and durability.

What Is a Customized Titanium Electrode?

A customized titanium electrode is an electrochemical component fabricated using titanium as the base material and tailored to specific requirements such as size, coating type, surface area, and current distribution. Unlike standard electrodes, customized versions can be optimized for particular electrochemical reactions, electrode potentials, and industrial environments.

Technical Parameters of Customized Titanium Electrodes

|

Parameter |

Typical Range |

|

Substrate Material |

Pure Titanium (Grade 1 / 2) |

|

Coating Type |

Ru-Ir, Ir-Ta, PbO₂, Pt, etc. |

|

Coating Thickness |

5–20 μm |

|

Operating Current Density |

10–5000 A/m² |

|

Cell Voltage |

1.5–4.5 V |

|

Operating Temperature |

≤ 80°C |

|

Service Life |

3–10 years (depending on environment) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages of a Customized Titanium Electrode

High Corrosion Resistance

Titanium itself forms a stable oxide film, making it resistant to most acids, alkalis, and chlorides — ensuring a long service life even under harsh industrial conditions.

Excellent Electrochemical Performance

By adjusting the coating composition, the electrode can achieve desired properties such as low oxygen evolution potential or high chlorine evolution efficiency.

Energy Efficiency

Customized titanium electrodes ensure optimal current distribution, reducing energy loss and improving the efficiency of electrochemical reactions.

Extended Lifespan

With proper coating and structural design, the service life of a customized titanium electrode can exceed 5–10 times that of conventional electrodes.

Adaptability and Flexibility

Each electrode can be adapted for specific industrial needs, including geometry, current density, and electrolyte type — something impossible with standard electrodes.

Types of Customized Titanium Electrodes

1. MMO Coated Titanium Electrode

Also known as Mixed Metal Oxide Electrode, this type features a coating of noble metal oxides such as IrO₂, RuO₂, or Ta₂O₅. It is widely used in electrolysis, cathodic protection, and wastewater treatment.

2. Platinum Coated Titanium Electrode

Ideal for high-purity processes such as electroplating, fuel cells, and laboratory electrolysis, this electrode combines titanium’s strength with platinum’s catalytic activity.

3. Lead Dioxide Coated Titanium Electrode

The PbO₂-titanium electrode offers strong oxidation ability and is commonly applied in organic pollutant degradation and electrochemical synthesis.

4. Dimensionally Stable Anode (DSA)

Developed for industrial electrolysis, DSA titanium electrodes provide stable performance, low overpotential, and minimal dimensional change during operation.

Applications of Customized Titanium Electrodes

1. Wastewater Treatment

Customized titanium electrodes are extensively used in electrochemical oxidation, electrocoagulation, and electro-Fenton systems for removing COD, ammonia, and organic pollutants. The coating composition and structure can be tailored for various wastewater types — from textile effluent to coking wastewater.

2. Electroplating Industry

In chromium plating, nickel plating, and copper plating, titanium electrodes with PbO₂ or platinum coatings provide excellent stability and current efficiency. Customized designs allow easy installation in existing plating baths.

3. Chlor-Alkali Industry

MMO-coated titanium anodes are crucial in chlorine and sodium hydroxide production. Their design minimizes energy consumption and enhances chlorine purity.

4. Hydrogen and Oxygen Generation

Customized titanium electrodes are applied in electrolyzers for hydrogen production. The coating and surface structure are optimized for high catalytic efficiency and long service life.

5. Cathodic Protection

In marine engineering and storage tanks, titanium electrodes with MMO coating act as long-lasting anodes that prevent corrosion of steel structures.

Real-World Case Studies

1: Electrochemical Wastewater Treatment in Korea

A Korean electronics company needed an efficient oxidation electrode for treating high-COD wastewater. Baoji ShenAo supplied a customized titanium electrode with Ru-Ir coating on a mesh structure. The result: COD reduction efficiency increased by 35%, and electrode life exceeded three years of continuous operation.

2: Hydrogen Generation System in Germany

For a hydrogen generator manufacturer, a platinum-coated titanium electrode was developed with optimized surface roughness. The system achieved 20% higher hydrogen yield and reduced voltage loss by 0.3V compared to standard electrodes.

3: Chlor-Alkali Electrolysis in India

Customized DSA titanium anodes with Ir-Ta coating were used for chlorine evolution. The client reported 15% energy savings and stable output after one year of operation.

Industry Sectors Benefiting from Customized Titanium Electrodes

Water Treatment & Environmental Protection

Electrochemical Synthesis

Metal Finishing & Electroplating

Energy Storage & Hydrogen Production

Chemical Manufacturing

Marine Engineering & Cathodic Protection

Each of these sectors demands precise electrode design and coating selection — and that’s exactly what customized titanium electrodes deliver.

Quality Assurance and International Standards

Baoji City ShenAo Metal Materials Co., Ltd. strictly follows ISO9001 quality management standards. Every customized titanium electrode undergoes:

Coating Composition Analysis (XRD, EDS)

Adhesion Testing

Accelerated Life Testing

Electrochemical Polarization Analysis

|

|

|

|

|

|

|

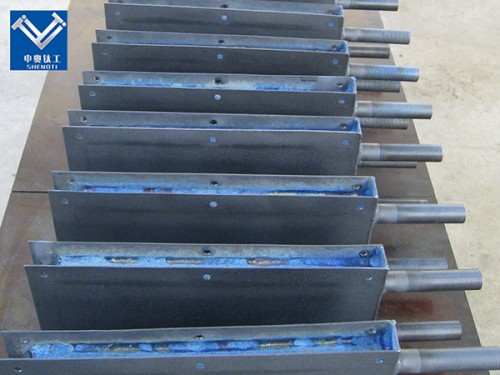

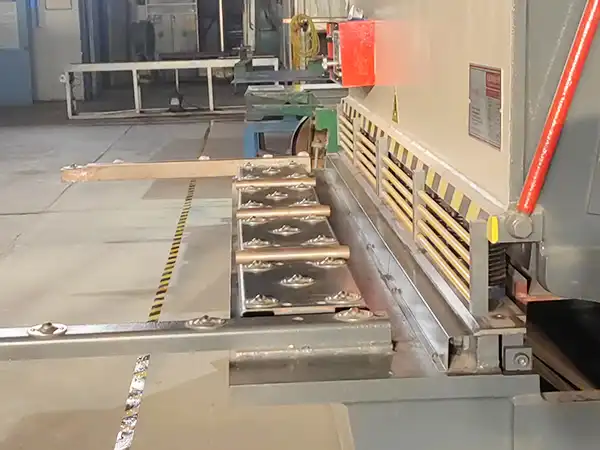

Product production process

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Baoji ShenAo for Customized Titanium Electrodes?

Professional Design Support:

Our engineers work with you to develop electrode geometry, coating system, and current efficiency to fit your exact process.

Advanced Manufacturing Equipment:

We utilize precise coating furnaces, vacuum annealing, and automatic sandblasting systems to ensure uniformity and durability.

Extensive Industry Experience:

With more than 15 years in the titanium electrode industry, we’ve served over 200 clients worldwide across 30+ industries.

Our electrodes meet or exceed international standards such as ASTM B265 for titanium substrates and GB/T 24511 for explosion-bonded composite materials.

Competitive Pricing & Timely Delivery:

Direct factory supply from Baoji — China’s titanium valley — ensures both cost efficiency and fast global shipment.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

1. What coatings are available for our titanium electrodes?

We offer coatings such as Ruthenium-Iridium, Platinum, and other precious metals to enhance performance for specific applications.

2. How are the electrodes customized?

We work closely with clients to tailor dimensions, coatings, and technical specifications based on operational requirements.

3. What is the typical lead time for production and delivery?

Depending on the order size and customization, the lead time ranges from 2–4 weeks.

4. Can these electrodes be used in high-temperature environments?

Yes, our electrodes are designed to operate efficiently in temperatures up to 300°C.

Contact Us

We are here to assist you with all your titanium electrode needs.Our customized titanium electrodes deliver the perfect combination of performance, durability, and innovation. Contact us today to discuss your project requirements!

Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

Contact: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

YOU MAY LIKE