In Which Industries Are Titanium Aluminum Clad Plates Mainly Used?

2025-04-26 10:58:15

In Which Industries Are Titanium Aluminum Clad Plates Mainly Used?

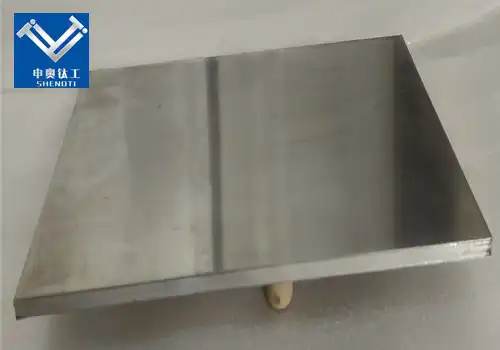

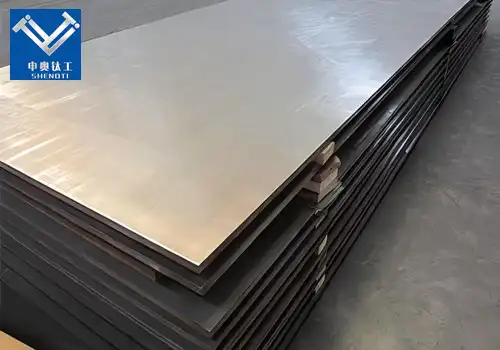

Titanium aluminum clad plates are engineered composites that combine the superior corrosion resistance and high-temperature stability of titanium with the lightweight and high thermal conductivity of aluminum. This unique combination of properties makes them indispensable across a range of industries, including aerospace, marine engineering, power generation, chemical processing, and more.

Aerospace Industry: Why Are Titanium Aluminum Clad Plates Preferred in Aerospace Applications?

The aerospace industry demands materials that offer high strength-to-weight ratios, excellent corrosion resistance, and the ability to withstand extreme temperatures. Titanium aluminum clad plates meet these requirements, making them ideal for various aerospace applications.

Applications in Aerospace

Structural Components: The lightweight nature of aluminum combined with the strength of titanium makes these clad plates suitable for aircraft structural components, reducing overall weight and improving fuel efficiency.

Engine Parts: Titanium aluminum clad plates are used in engine components such as compressor blades and turbine parts, where high-temperature resistance and strength are crucial.

Fuel Tanks: The corrosion resistance of titanium ensures the longevity and safety of fuel storage systems in aircraft.

Advantages

Weight Reduction: The use of titanium aluminum clad plates contributes to significant weight savings, which is critical in aerospace applications.

Enhanced Performance: Improved thermal stability and corrosion resistance lead to better performance and longer service life of aerospace components.

Marine Engineering: How Do Titanium Aluminum Clad Plates Benefit Marine Applications?

Marine environments are highly corrosive due to constant exposure to seawater. Titanium aluminum clad plates offer exceptional resistance to corrosion, making them ideal for marine engineering applications.

Applications in Marine Engineering

Shipbuilding: These clad plates are used in hull construction and other structural components, providing durability and resistance to seawater corrosion.

Desalination Plants: Titanium aluminum clad plates are employed in heat exchangers and other equipment within desalination facilities, ensuring longevity and efficiency.

Offshore Platforms: The strength and corrosion resistance of these materials make them suitable for offshore oil and gas platforms.

Advantages

Corrosion Resistance: Titanium's natural resistance to seawater corrosion extends the lifespan of marine structures.

Maintenance Reduction: The durability of these clad plates reduces the need for frequent maintenance, leading to cost savings.

Power Generation: What Role Do Titanium Aluminum Clad Plates Play in Power Plants?

In power generation, especially in environments involving high temperatures and corrosive substances, materials must withstand harsh conditions. Titanium aluminum clad plates are utilized in various components within power plants.

Applications in Power Generation

Heat Exchangers: These clad plates are used in heat exchangers due to their excellent thermal conductivity and corrosion resistance.

Condensers: In both fossil fuel and nuclear power plants, titanium aluminum clad plates are employed in condensers to improve efficiency and durability.

Flue Gas Desulfurization Systems: The corrosion resistance of titanium is beneficial in systems designed to remove sulfur dioxide from exhaust gases.

Advantages

Thermal Efficiency: The high thermal conductivity of aluminum enhances the efficiency of heat transfer systems.

Durability: The combination of titanium and aluminum ensures components can withstand the demanding conditions within power plants.

Chemical Processing: Why Are Titanium Aluminum Clad Plates Used in Chemical Industries?

Chemical processing industries often involve handling corrosive substances and operating under high temperatures. Titanium aluminum clad plates offer the necessary resistance and strength for such environments.

Applications in Chemical Processing

Reactors and Vessels: These clad plates are used in constructing reactors and storage vessels that handle corrosive chemicals.

Heat Exchangers: The thermal properties of aluminum combined with titanium's corrosion resistance make these plates suitable for heat exchangers in chemical plants.

Piping Systems: Titanium aluminum clad plates are used in piping systems to transport aggressive chemicals safely.

Advantages

Chemical Resistance: Titanium provides excellent resistance to a wide range of chemicals, ensuring the integrity of processing equipment.

Operational Safety: The durability of these materials enhances the safety of chemical processing operations.

Automotive Industry: How Are Titanium Aluminum Clad Plates Utilized in Automotive Applications?

The automotive industry seeks materials that contribute to weight reduction without compromising strength and safety. Titanium aluminum clad plates offer these benefits, making them increasingly popular in automotive applications.

Applications in Automotive Industry

Exhaust Systems: The high-temperature resistance of titanium makes these clad plates suitable for exhaust components.

Structural Components: The strength and lightweight nature of these materials are advantageous in manufacturing vehicle frames and other structural parts.

Battery Enclosures: In electric vehicles, titanium aluminum clad plates are used for battery enclosures, providing protection and thermal management.

Advantages

Fuel Efficiency: Weight reduction leads to improved fuel efficiency and reduced emissions.

Performance Enhancement: The strength and durability of these materials contribute to the overall performance and safety of vehicles.

Medical Equipment: What Makes Titanium Aluminum Clad Plates Suitable for Medical Applications?

In the medical field, materials must be biocompatible, corrosion-resistant, and durable. Titanium aluminum clad plates meet these criteria, making them suitable for various medical applications.

Applications in Medical Equipment

Surgical Instruments: The strength and corrosion resistance of these materials are beneficial in manufacturing surgical tools.

Implants: Titanium's biocompatibility makes it ideal for implants, while aluminum contributes to weight reduction.

Medical Devices: These clad plates are used in various medical devices requiring durability and resistance to bodily fluids.

Advantages

Biocompatibility: Titanium's compatibility with the human body reduces the risk of adverse reactions.

Longevity: The durability of these materials ensures the longevity of medical equipment and implants.

Architectural Applications: How Do Titanium Aluminum Clad Plates Enhance Building Structures?

In architecture, materials that offer aesthetic appeal, durability, and resistance to environmental factors are highly valued. Titanium aluminum clad plates provide these benefits, making them suitable for various architectural applications.

Applications in Architecture

Facades and Cladding: These clad plates are used in building facades and cladding systems, offering a modern appearance and protection against the elements.

Roofing Systems: The lightweight nature and corrosion resistance of these materials make them ideal for roofing applications.

Interior Design: Titanium aluminum clad plates are employed in interior design elements, providing a sleek and durable finish.

Advantages

Aesthetic Appeal: The unique appearance of titanium and aluminum adds a modern touch to building designs.

Environmental Resistance: These materials withstand harsh weather conditions, reducing maintenance requirements.

Frequently Asked Questions

What Are the Key Properties of Titanium Aluminum Clad Plates?

Titanium aluminum clad plates combine the beneficial properties of both metals:

Corrosion Resistance: Titanium offers excellent resistance to various corrosive environments.

Lightweight: Aluminum's low density contributes to the overall weight reduction of components.

High Strength: The combination of metals provides a high strength-to-weight ratio.

Thermal Conductivity: Aluminum enhances the thermal conductivity of the clad plate.

_1752287642525.webp)